Общий каталог FANAR 2021 - страница 328

Навигация

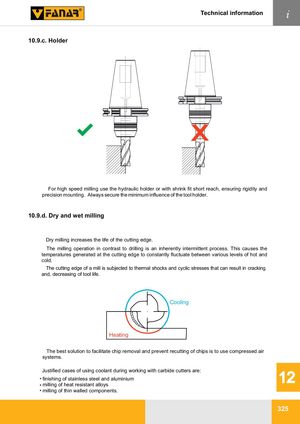

Technical information i 10.9.c. Holder For high speed milling use the hydraulic holder or with shrink fit short reach, ensuring rigidity and precision mounting. Always secure the minimum influence of the tool holder. 10.9.d. Dry and wet milling Dry milling increases the life of the cutting edge. The milling operation in contrast to drilling is an inherently intermittent process. This causes the temperatures generated at the cutting edge to constantly fluctuate between various levels of hot and cold. The cutting edge of a mill is subjected to thermal shocks and cyclic stresses that can result in cracking and, decreasing of tool life. Cooling Heating The best solution to facilitate chip removal and prevent recutting of chips is to use compressed air systems. Justified cases of using coolant during working with carbide cutters are: finishing of stainless steel and aluminium 12 milling of heat resistant alloys milling of thin walled components. 325

Общий каталог FANAR 2018

Общий каталог FANAR 2018 Каталог FANAR цельные твердосплавные фрезы

Каталог FANAR цельные твердосплавные фрезы