Общий каталог FANAR 2021 - страница 314

Навигация

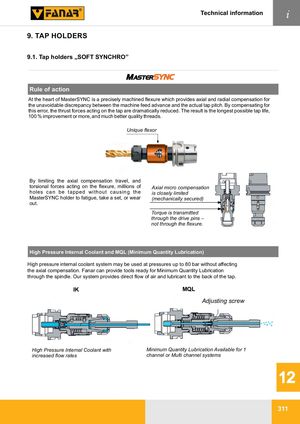

Technical information i 9. TAP HOLDERS 9.1. Tap holders „SOFT SYNCHRO” MASTERSYNC Rule of action At the heart of MasterSYNC is a precisely machined flexure which provides axial and radial compensation for the unavoidable discrepancy between the machine feed advance and the actual tap pitch. By compensating for this error, the thrust forces acting on the tap are dramatically reduced. The result is the longest possible tap life, 100 % improvement or more, and much better quality threads. Unique flexor By limiting the axial compensation travel, and torsional forces acting on the flexure, millions of Axial micro compensation holes can be tapped without causing the is closely limited MasterSYNC holder to fatigue, take a set, or wear (mechanically secured) out. Torque is transmitted through the drive pins – not through the flexure. High Pressure Internal Coolant and MQL (Minimum Quantity Lubrication) High pressure internal coolant system may be used at pressures up to 80 bar without affecting the axial compensation. Fanar can provide tools ready for Minimum Quantity Lubrication through the spindle. Our system provides direct flow of air and lubricant to the back of the tap. IK MQL Adjusting screw High Pressure Internal Coolant with Minimum Quantity Lubrication Available for 1 increased flow rates channel or Multi channel systems 12 311

Общий каталог FANAR 2018

Общий каталог FANAR 2018 Каталог FANAR цельные твердосплавные фрезы

Каталог FANAR цельные твердосплавные фрезы