Общий каталог Dijet 2018 - страница 530

Навигация

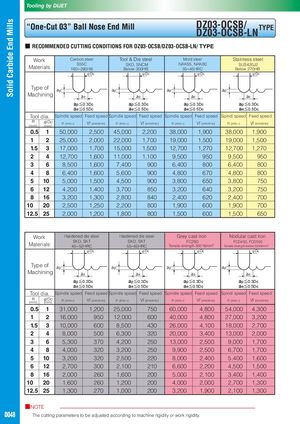

Solid Carbide End Mills Tooling by DIJET “One-Cut 03” Ball Nose End Mill DDZZ0033--OOCCSSBB/-LN TYPE ■ RECOMMENDED CUTTING CONDITIONS FOR DZ03-OCSB/DZ03-OCSB-LN/ TyPE Work Carbon steel Tool & Die steel Mold steel Stainless steel Materials S55C180~~280HB SKD, SNCMBelow 300HB NAK55, NAK80 SUS420J235~~45HRCBelow 270HB φDc φDc φDc φDc Type of ap ap ap ap Machining ae ae ae ae ap≦0.3Dc ap≦0.3Dc ap≦0.3Dc ap≦0.3Dc ae≦0.5Dc ae≦0.5Dc ae≦0.5Dc ae≦0.5Dc Tool dia. Spindle speed Feed speed Spindle speed Feed speed Spindle speed Feed speed Spindl speed Feed speed R φDc(mm)(mm)n (min-1) Vf (mm/min) n (min-1) Vf (mm/min) n (min-1) Vf (mm/min) n (min-1) Vf (mm/min) 0.5 1 50,000 2,500 45,000 2,200 38,000 1,900 38,000 1,900 1 2 25,000 2,000 22,000 1,700 19,000 1,500 19,000 1,500 1.5 3 17,000 1,700 15,000 1,500 12,700 1,270 12,700 1,270 2 4 12,700 1,600 11,000 1,100 9,500 950 9,500 950 3 6 8,500 1,600 7,400 900 6,400 800 6,400 800 4 8 6,400 1,600 5,600 900 4,800 670 4,800 800 5 10 5,000 1,500 4,500 900 3,800 650 3,800 750 6 12 4,200 1,400 3,700 850 3,200 640 3,200 750 8 16 3,200 1,300 2,800 840 2,400 620 2,400 700 10 20 2,500 1,250 2,200 800 1,900 600 1,900 700 12.5 25 2,000 1,200 1,800 800 1,500 600 1,500 650 Work Hardened die steel Hardened die steel Grey cast iron Nodular cast iron Materials SKD, SKT45~52HRC SKD, SKT FC250 FCD450, FCD55055~60HRCTensile strength 350 N/mm2Tensile strength below 550N/mm2 φDc φDc φDc φDc Type of ap ap ap ap Macchhininiinngg ae ae ae ae ap≦0.3Dc ap≦0.3Dc ap≦0.3Dc ap≦0.3Dc ae≦0.5Dc ae≦0.5Dc ae≦0.5Dc ae≦0.5Dc Tool dia. Spindle speed Feed speed Spindle speed Feed speed Spindle speed Feed speed Spindl speed Feed speed R(mm) φDc(mm) n (min-1) Vf (mm/min) n (min-1) Vf (mm/min) n (min-1) Vf (mm/min) n (min-1) Vf (mm/min) 0.5 1 31,000 1,200 25,000 750 60,000 4,800 54,000 4,300 1 2 16,000 950 12,000 600 40,000 4,800 27,000 3,200 1.5 3 10,000 600 8,500 430 26,000 4,100 18,000 2,700 2 4 8,000 500 6,300 320 20,000 3,400 13,000 2,000 3 6 5,300 370 4,200 250 13,000 2,500 9,000 1,700 4 8 4,000 320 3,200 250 9,900 2,500 6,700 1,700 5 10 3,200 320 2,500 220 8,000 2,400 5,400 1,600 6 12 2,700 300 2,100 210 6,600 2,200 4,500 1,500 8 16 2,000 260 1,600 200 5,000 2,100 3,400 1,400 10 20 1,600 260 1,200 200 4,000 2,000 2,700 1,300 12.5 25 1,300 270 1,000 200 3,200 1,900 2,100 1,300 ■NOTE D048 The cutting parameters to be adjusted according to machine rigidity or work rigidity.

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском