Общий каталог Dijet 2018 - страница 457

Навигация

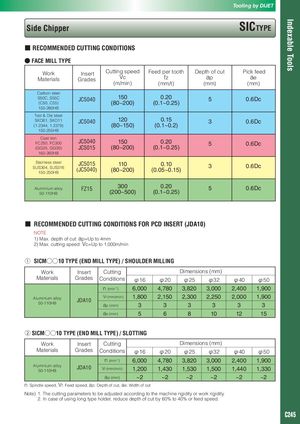

Indexable Tools Tooling by DIJET ISnidexCahbilpepToeor ls SSDICSTTYYPPEE ■ RECOMMENDED CUTTING CONDITIONS ● FACE MILL TYPE WorkMaterials InsertGradesCutting speed Feed per toothVcfz(m/min)(mm/t)Depth of cutap(mm)Pick feedae(mm) Carbon steel S50C, S55C(C50, C55) JC5040 150(80~200) 0.20(0.1~0.25) 5 0.6Dc 150-280HB Tool & Die steel SKD61, SKD11(1.2344, 1.2379)JC5040 120(80~150) 0.15(0.1~0.2) 3 0.6Dc 150-255HB Cast ironFC250, FC300JC5040 150 0.20(GG25, GG30)JC5015(80~200)(0.1~0.25)50.6Dc 160-260HB Stainless steel JC5015 110 0.10SUS304, SUS316150-250HB(JC5040)(80~200)(0.05~0.15)30.6Dc Aluminium alloy50-110HB FZ15 300(200~500) 0.20(0.1~0.25) 5 0.6Dc ■ RECOMMENDED CUTTING CONDITIONS FOR PCD INSERT (JDA10) NOTE 1) Max. depth of cut: ap=Up to 4mm 2) Max. cutting speed: Vc=Up to 1,000m/min ① SICM○○10 TYPE (END MILL TYPE) / SHOULDER MILLING Work Insert Cutting Dimensions (mm) Materials Grades Conditions φ16 φ20 φ25 φ32 φ40 φ50 n (min-1) 6,000 4,780 3,820 3,000 2,400 1,900 Aluminium alloy50-110HBJDA10 Vf (mm/min) 1,800 2,150 2,300 2,250 2,000 1,900ap (mm)333333 ae (mm) 5 6 8 10 12 15 ② SICM○○10 TYPE (END MILL TYPE) / SLOTTING Work Insert Cutting Dimensions (mm) Materials Grades Conditions φ16 φ20 φ25 φ32 φ40 φ50 n (min-1) 6,000 4,780 3,820 3,000 2,400 1,900 Aluminium alloy50-110HBJDA10 Vf (mm/min) 1,200 1,430 1,530 1,500 1,440 1,330 ap (mm) ~2 ~2 ~2 ~2 ~2 ~2 n: Spindle speed, Vf: Feed speed, ap: Depth of cut, ae: Width of cut Note) 1. The cutting parameters to be adjusted according to the machine rigidity or work rigidity. 2. In case of using long type holder, reduce depth of cut by 60% to 40% or feed speed. C245

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском