Общий каталог Dijet 2018 - страница 456

Навигация

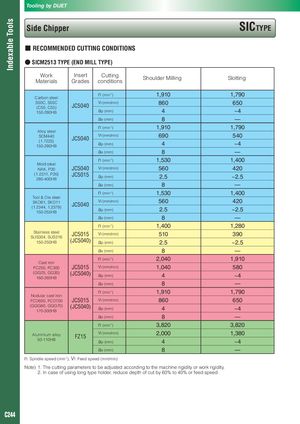

Indexable Tools Tooling by DIJET ISnidexCahbilpepTeorols SSDICSTTYYPPEE ■ RECOMMENDED CUTTING CONDITIONS ● SICM2513 TYPE (END MILL TYPE) Work Insert CuttingMaterialsGradesconditionsShoulder Milling Slotting n (min-1)Carbon steel 1,910 1,790 S50C, S55C(C50, C55)150-280HBJC5040Vf (mm/min)ap (mm) 8604 650~4 ae (mm) 8 — n (min-1) 1,910 1,790 Alloy steel SCM440(1.7223)150-280HBJC5040 Vf (mm/min)ap (mm) 6904 540~4 ae (mm) 8 — n (min-1) 1,530 1,400 Mold steel NAK, P20 JC5040 Vf (mm/min) 560 420 (1.2311, P20)280-400HBJC5015 ap (mm) 2.5 ~2.5 ae (mm) 8 — n (min-1) 1,530 1,400 Tool & Die steel SKD61, SKD11(1.2344, 1.2379)150-255HBJC5040Vf (mm/min)ap (mm)5602.5 420~2.5 ae (mm) 8 — n (min-1) 1,400 1,280 Stainless steelSUS304, SUS316150-250HBJC5015(JC5040)Vf (mm/min)ap (mm)5102.5 390~2.5 ae (mm) 8 — n (min-1) 2,040 1,910 Cast iron FC250, FC300 JC5015 Vf (mm/min) 1,040 580 (GG25, GG30)160-260HB(JC5040) ap (mm) 4 ~4 ae (mm) 8 — n (min-1) 1,910 1,790 Nodular cast iron FCD600, FCD700 JC5015 Vf (mm/min) 860 650 (GGG60, GGG70)170-300HB(JC5040) ap (mm) 4 ~4 ae (mm) 8 — n (min-1) 3,820 3,820 Aluminium alloy FZ15 Vf (mm/min) 2,000 1,380 50-110HB ap (mm) 4 ~4 ae (mm) 8 — n: Spindle speed (min-1), Vf: Feed speed (mm/min) Note) 1. The cutting parameters to be adjusted according to the machine rigidity or work rigidity. 2. In case of using long type holder, reduce depth of cut by 60% to 40% or feed speed. C244

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском