Общий каталог Dijet 2018 - страница 454

Навигация

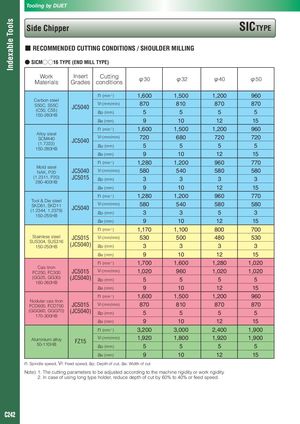

Indexable Tools Tooling by DIJET ISnidexCahbilpepTeorols SSDICSTTYYPPEE ■ RECOMMENDED CUTTING CONDITIONS / SHOULDER MILLING ● SICM○○16 TYPE (END MILL TYPE) Work Insert CuttingMaterialsGradesconditionsφ30 φ32 φ40 φ50 n (min-1) 1,600 1,500 1,200 960 Carbon steelS50C, S55C(C50, C55)150-280HBJC5040Vf (mm/min)ap (mm)8705 8105 870 87055 ae (mm) 9 10 12 15 n (min-1) 1,600 1,500 1,200 960 Alloy steelSCM440(1.7223)150-280HBJC5040Vf (mm/min)ap (mm)7205 6805 720 72055 ae (mm) 9 10 12 15 n (min-1) 1,280 1,200 960 770 Mold steelNAK, P20JC5040 Vf (mm/min) 580 540 580 580 (1.2311, P20)280-400HBJC5015ap (mm) 3 3 3 3 ae (mm) 9 10 12 15 n (min-1) 1,280 1,200 960 770 Tool & Die steelSKD61, SKD11(1.2344, 1.2379)150-255HBJC5040Vf (mm/min)ap (mm)58035403 580 58053 ae (mm) 9 10 12 15 n (min-1) 1,170 1,100 800 700 Stainless steel JC5015 Vf (mm/min) 530 500 480 530 SUS304, SUS316150-250HB(JC5040)ap (mm) 3 3 3 3 ae (mm) 9 10 12 15 n (min-1) 1,700 1,600 1,280 1,020 Cas tiron FC250, FC300 JC5015 Vf (mm/min) 1,020 960 1,020 1,020 (GG25, GG30)160-260HB(JC5040)ap (mm) 5 5 5 5 ae (mm) 9 10 12 15 n: Spindle speed, Vf: Feed speed, ap: Dnep(tmhino-f1)cut, ae: Width1o,f6c0u0t 1,500 1,200 960 No(FNGteCoG)Dd2G16u..60laIT00nrh,,cceGFaaCGcssDueGti7trt7oo0in0nf0g)uspina(JJgraCClmo55ne00gt14e50trys)pteo 170-300HB hbVoef l(dmaedmrj,u/mrseitnde)ducaecdcoerpdthin8go7ft0coutthbeym6a0c%hintoe84ri10g%0idiotyr ap (mm) 5 5 foerewdosrpkeriegd8id.7it0y. 5 8705 ae (mm) 9 10 12 15 n (min-1) 3,200 3,000 2,400 1,900 Aluminium alloy50-110HBFZ15 Vf (mm/min)ap (mm)1,9205 1,8005 1,920 1,90055 ae (mm) 9 10 12 15 n: Spindle speed, Vf: Feed speed, ap: Depth of cut, ae: Width of cut Note) 1. The cutting parameters to be adjusted according to the machine rigidity or work rigidity. 2. In case of using long type holder, reduce depth of cut by 60% to 40% or feed speed. C242

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском