Общий каталог Dijet 2018 - страница 453

Навигация

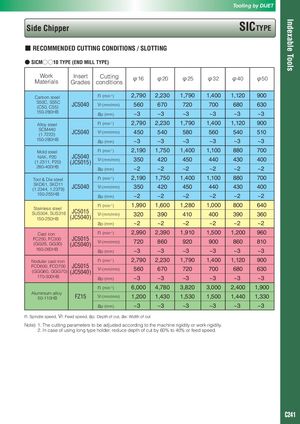

Indexable Tools Tooling by DIJET ISnidexCahbilpepToeor ls SSDICSTTYYPPEE ■ RECOMMENDED CUTTING CONDITIONS / SLOTTING ● SICM○○10 TYPE (END MILL TYPE) WorkMaterials Insert CuttingGradesconditionsφ16 φ20 φ25 φ32 φ40 φ50 Carbon steel n (min-1) 2,790 2,230 1,790 1,400 1,120 900 S50C, S55C(C50, C55)JC5040 Vf (mm/min) 560 670 720 700 680 630 150-280HB ap (mm) ~3 ~3 ~3 ~3 ~3 ~3 Alloy steel n (min-1) 2,790 2,230 1,790 1,400 1,120 900 SCM440(1.7223) JC5040 Vf (mm/min) 450 540 580 560 540 510 150-280HB ap (mm) ~3 ~3 ~3 ~3 ~3 ~3 Mold steel n (min-1) 2,190 1,750 1,400 1,100 880 700 NAK, P20(1.2311, P20)JC5040(JC5015)Vf (mm/min)350 420 450 440 430 400 280-400HB ap (mm) ~2 ~2 ~2 ~2 ~2 ~2 Tool & Die steel n (min-1) 2,190 1,750 1,400 1,100 880 700 SKD61, SKD11(1.2344, 1.2379)JC5040Vf (mm/min) 350 420 450 440 430 400 150-255HB ap (mm) ~2 ~2 ~2 ~2 ~2 ~2 Stainless steelSUS304, SUS316150-250HBJC5015(JC5040)n (min-1)Vf (mm/min)1,9901,6001,2803203904101,000400800390 640360 ap (mm) ~2 ~2 ~2 ~2 ~2 ~2 Cast iron n (min-1) 2,990 2,390 1,910 1,500 1,200 960 FC250, FC300(GG25, GG30)JC5015(JC5040)Vf (mm/min)720 860 920 900 860 810 160-260HB ap (mm) ~3 ~3 ~3 ~3 ~3 ~3 Nodular cast iron n (min-1) 2,790 2,230 1,790 1,400 1,120 900 FCD600, FCD700 JC5015(GGG60, GGG70)(JC5040)Vf (mm/min)560 670 720 700 680 630 170-300HB ap (mm) ~3 ~3 ~3 ~3 ~3 ~3 n (min-1) 6,000 4,780 3,820 3,000 2,400 1,900 Aluminium alloy50-110HBFZ15 Vf (mm/min) 1,200 1,430 1,530 1,500 1,440 1,330 ap (mm) ~3 ~3 ~3 ~3 ~3 ~3 n: Spindle speed, Vf: Feed speed, ap: Depth of cut, ae: Width of cut Note) 1. The cutting parameters to be adjusted according to the machine rigidity or work rigidity. 2. In case of using long type holder, reduce depth of cut by 60% to 40% or feed speed. C241

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском