Общий каталог Dijet 2018 - страница 443

Навигация

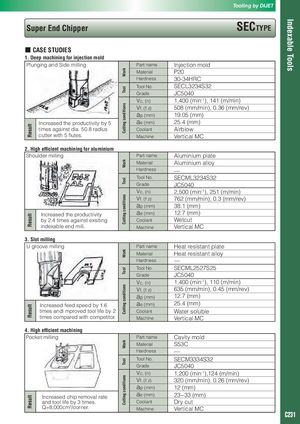

Indexable Tools ResultResultResultResult WorkToolCutting conditionsWorkToolCutting conditionsWorkToolCutting conditionsWorkToolCutting conditions Tooling by DIJET ISnudpeexraEbnledToCohlispper SEDCSTTYYPPEE ■ CASE STUDIES 1. Deep machining for injection mold Plunging and Side milling Part name Injection mold Material P20 Hardness 30-34HRC Tool No. SECL3234S32 Grade JC5040 Vc, (n) 1,400 (min-1), 141 (m/min) Vf, (f z) 508 (mm/min), 0.36 (mm/rev) ap (mm) 19.05 (mm) Increased the productivity by 5 ae (mm) 25.4 (mm) times against dia. 50.8 radius Coolant Airblow cutter with 5 flutes. Machine Vertical MC 2. High efficient machining for aluminium Shoulder milling Part name Aluminium plate Material Aluminium alloy Hardness — Tool No. SECML3234S32 Grade JC5040 Vc, (n) 2,500 (min-1), 251 (m/min) Vf, (f z) 762 (mm/min), 0.3 (mm/rev) ap (mm) 38.1 (mm) Increased the productivity ae (mm) 12.7 (mm) by 2.4 times against exsiting Coolant Wetcut indexable end mill. Machine Vertical MC 3. Slot milling U groove milling Part name Heat resistant plate Material Heat resistant alloy Hardness — Tool No. SECML2527S25 Grade JC5040 Vc, (n) 1,400 (min-1), 110 (m/min) Vf, (f z) 635 (mm/min), 0.45 (mm/rev) ap (mm) 12.7 (mm) Increased feed speed by 1.6 ae (mm) 25.4 (mm) times andi mproved tool life by 2 Coolant Water soluble times compared with competitor. Machine Vertical MC 4. High efficient machining Pocket milling Part name Cavity mold Material S53C Hardness — Tool No. SECM3334S32 Grade JC5040 Vc, (n) 1,200 (min-1),124 (m/min) Vf, (f z) 320 (mm/min), 0.26 (mm/rev) ap (mm) 12 (mm) Increased chip removal rate ae (mm) 23−33 (mm) and tool life by 3 times. Coolant Dry cut Q=8,000cm3/corner. Machine Vertical MC C231

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском