Общий каталог Dijet 2018 - страница 437

Навигация

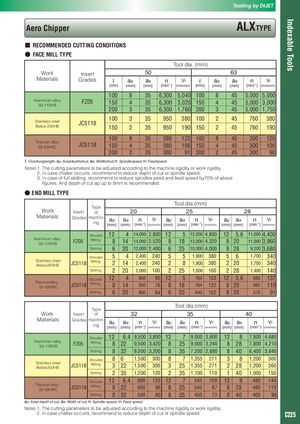

Indexable Tools Tooling by DIJET Aero Chipper ALXTYPE ■ RECOMMENDED CUTTING CONDITIONS ● FACE MILL TYPE Tool dia. (mm) Work Insert 50 63 Materials Grades ℓ ap ae n Vf ℓ ap ae n Vf (mm) (mm) (mm) (min-1) (mm/min) (mm) (mm) (mm) (min-1) (mm/min) 100 8 35 6,300 5,040 100 8 45 5,000 5,000 Aluminium alloy50-110HB FZ05 150 4 35 6,300 3,020 150 4 45 5,000 3,000 200 3 35 6,300 1,760 200 3 45 5,000 1,750 Stainless steelBelow 250HB 100 3 35 950 380 100 2 45 760 380JC5118150235950190150245760190 100 8 35 380 122 100 8 45 300 120 Titanium alloy35-43HRCJC5118 150 4 35 380 106 150 4 45 300 105 200 2 35 380 91 200 2 45 300 90 ℓ: Overhunglength, ap: Axialdepthofcut, ae: Widthofcut,n: Spindlespeed,Vf: Feedspeed Note) 1. The cutting parameters to be adjusted according to the machine rigidity or work rigidity. 2. In case chatter occurrs, recommend to reduce depth of cut or spindle speed. 3. In case of full slotting, recommend to reduce spindles peed and feed speed by70% of above figures. And depth of cut ap up to 8mm is recommended. ● END MILL TYPE Tool dia.(mm) Type Work Insert of 20 25 28 Materials Grades machin-ing ap(mm) ae(mm) n Vf ap(min-1)(mm/min)(mm)aen Vf(mm)(min-1)(mm/min)apae(mm)(mm)n Vf(min-1)(mm/min) Shoulder 12 4 14,000 2,800 12 5 12,000 4,800 12 5.6 11,000 4,400 Aluminium alloy50-110HBFZ05 Milling 8 14 14,000 2,520 8 18 12,000 4,320 8 20 11,000 3,960 Slotting 6 20 12,000 2,400 6 25 10,000 4,000 8 28 9,200 3,680 Shoulder 5 4 2,400 240 5 5 1,900 380 5 6 1,700 340 Stainless steelBelow250HBJC5118 Milling 2 14 2,400 240 2 8 1,900 380 2 20 1,700 340 Slotting 2 20 2,000 100 2 25 1,600 160 2 28 1,400 140 Shoulder 12 4 950 95 12 5 764 153 12 5.6 685 137 Titaniumalloy35-43HRCJC5118 Milling 8 14 950 76 8 18 764 122 8 20 685 110 Slotting 6 20 800 64 6 25 640 102 8 28 570 91 Tool dia.(mm) Type Work Insert of 32 35 40 Materials Grades machin-ing ap(mm) ae(mm) n Vf ap(min-1)(mm/min)(mm)ae(mm)nVf(min-1)(mm/min)apae(mm)(mm)n Vf(min-1)(mm/min) Shoulder 12 6.4 9,500 3,800 12 7 9,000 3,600 12 8 7,800 4,680 Aluminium alloy50-110HBFZ05 Milling 8 22 9,500 3,420 8 25 9,000 3,240 8 28 7,800 4,210 Slotting 8 32 8,000 3,200 8 35 7,200 2,880 8 40 6,400 3,840 Shoulder 8 6 1,500 300 8 7 1,355 271 3 8 1,200 360 Stainless steelBelow250HBJC5118 Milling 3 22 1,500 300 3 25 1,355 271 2 28 1,200 360 Slotting 2 35 1,200 120 2 35 1,100 110 1 40 1,000 150 Shoulder 12 6.4 600 120 12 7 545 109 12 8 480 144 Titanium alloy35-43HRCJC5118 Milling 8 22 600 96 8 25 545 87 8 28 480 115 Slotting 8 32 500 80 8 35 450 72 8 40 400 96 ap: Axial depth of cut, ae: Width of cut, n: Spindle speed, Vf: Feed speed Note) 1. The cutting parameters to be adjusted according to the machine rigidity or work rigidity. 2. In case chatter occurrs, recommend to reduce depth of cut or spindle speed. C225

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском