Общий каталог Dijet 2018 - страница 400

Навигация

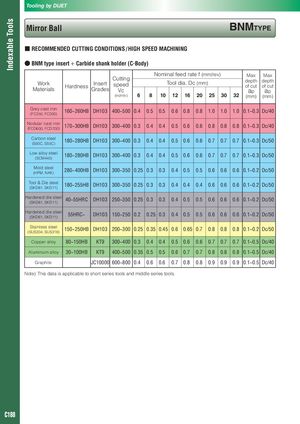

Indexable Tools Tooling by DIJET Mirror Ball BnMTyPE ■ RECOMMENDED CUTTING CONDITIONS / HIGH SPEED MACHINING ● BNM type insert + Carbide shank holder (C-Body) CuttingWorkMaterialsHardnessInsertGradesspeedVcNominal feed rate f (mm/rev)Tool dia. Dc (mm)MaxMaxdepthdepthof cutof cutapap (m/min) 6 8 10 12 16 20 25 30 32 (mm) (mm) Grey cast iron(FC250, FC300)160~260HBDH103400~500 0.4 0.5 0.5 0.6 0.8 0.8 1.0 1.0 1.0 0.1~0.3 Dc/40 Nodular cast iron(FCD600, FCD700)170~300HBDH103300~400 0.3 0.4 0.4 0.5 0.6 0.6 0.8 0.8 0.8 0.1~0.3 Dc/40 Carbon steel(S50C, S55C)180~280HBDH103300~400 0.3 0.4 0.4 0.5 0.6 0.6 0.7 0.7 0.7 0.1~0.3 Dc/50 Low alloy steel(SCM440)180~280HBDH103 300~400 0.3 0.4 0.4 0.5 0.6 0.6 0.7 0.7 0.7 0.1~0.3 Dc/50 Mold steel(HPM, NAK)280~400HBDH103 300~350 0.25 0.3 0.3 0.4 0.5 0.5 0.6 0.6 0.6 0.1~0.2 Dc/50 Tool & Die steel(SKD61, SKD11)180~255HBDH103300~350 0.25 0.3 0.3 0.4 0.4 0.4 0.6 0.6 0.6 0.1~0.2 Dc/50 Hardened die steel(SKD61, SKD11)40~55HRCDH103250~350 0.25 0.3 0.3 0.4 0.5 0.5 0.6 0.6 0.6 0.1~0.2 Dc/50 Hardened die steel(SKD61, SKD11)55HRC~DH103150~250 0.2 0.25 0.3 0.4 0.5 0.5 0.6 0.6 0.6 0.1~0.2 Dc/50 Stainless steel(SUS304, SUS316)150~250HBDH103200~300 0.25 0.35 0.45 0.6 0.65 0.7 0.8 0.8 0.8 0.1~0.2 Dc/50 Copper alloy 80~150HB KT9 300~400 0.3 0.4 0.4 0.5 0.6 0.6 0.7 0.7 0.7 0.1~0.5 Dc/40 Aluminium alloy 30~100HB KT9 400~500 0.35 0.5 0.5 0.6 0.7 0.7 0.8 0.8 0.8 0.1~0.5 Dc/40 Graphite JC10000 600~800 0.4 0.6 0.6 0.7 0.8 0.8 0.9 0.9 0.9 0.1~0.5 Dc/40 Note) This data is applicable to short series tools and middle series tools. C188

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском