Общий каталог Dijet 2018 - страница 380

Навигация

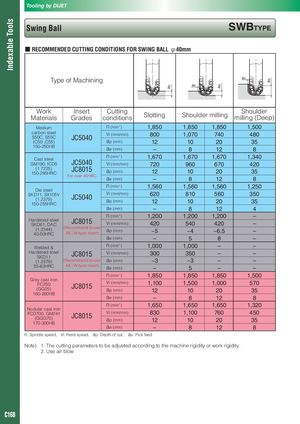

Indexable Tools ap ap ap Tooling by DIJET Swing Ball SWBTyPE ■ RECOMMENDED CUTTING CONDITIONS FOR SWING BALL φ40mm Type of Machining ae ae WorkMaterials Insert CuttingGradesconditionsSlotting Shoulder milling Shouldermilling (Deep) Medium n (min-1) 1,850 1,850 1,850 1,500 carbon steelS50C, S55C(C50 ,C55)JC5040Vf (mm/min)ap (mm) 80012 1,070 7401020 48035 150-250HB ae (mm) – 8 12 8 Cast steelGM190, ICD5JC5040 n (min-1)Vf (mm/min)1,670720 1,670 1,670960670 1,340420 (1.7225)150-285HRCJC8015 ap (mm)For over 40HRCae (mm)12– 10 20812 358 n (min-1) 1,560 1,560 1,560 1,250 Die steel SKD11, SX105V(1.2379)JC5040150-255HRC Vf (mm/min)ap (mm) 62012 810 5601020 35035 ae (mm) – 8 12 4 n (min-1) 1,200 1,200 1,200 – Hardened steelSKD61, DACJC8015 Vf (mm/min) 420 540 420 – (1.2344)40-50HRC(Recommend to use-M○W type insert)ap (mm)~5 ~4 ~6.5 – ae (mm) – 5 8 – Welded & n (min-1) 1,000 1,000 – – Hardened steelSKD11JC8015(1.2379)(Recommend to useVf (mm/min)ap (mm)300~3 350 –~3– –– 55-63HRC -M○W type insert) ae (mm) – 5 – – n (min-1) 1,850 1,850 1,850 1,500 Grey cast ironFC250(GG25)JC8015 Vf (mm/min)ap (mm)160-260HBae (mm)1,10012–1,500 1,0001020812 570358 n (min-1) 1,650 1,650 1,650 1,320 Nodular cast iron FCD700, GM241(GGG70)JC8015 Vf (mm/min)ap (mm)170-300HB83012 1,100 7601020 45035 ae (mm) – 8 12 8 n: Spindle speed, Vf: Feed speed, ap: Depth of cut, ae: Pick feed Note) 1. The cutting parameters to be adjusted according to the machine rigidity or work rigidity. 2. Use air blow C168

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском