Общий каталог Dijet 2018 - страница 326

Навигация

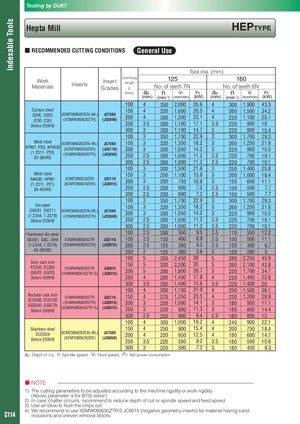

Indexable Tools Tooling by DIJET Hepta Mill HEPTyPE ■ RECOMMENDED CUTTING CONDITIONS General Use Tool dia. (mm) WorkMaterials Inserts Insert Overhunglength 125 160Gradesℓ(mm)No. of teeth 7NapnVfPcNo. of teeth 8NapnVfPc (mm) (min-1) (mm/min) (kW) (mm) (min-1) (mm/min) (kW) 100 4 350 2,000 35.6 4 300 1,900 43.3 Carbon steel 150 4S50C, S55CXDMT080620ZER(-ML)JC7560(C50, C55)(XDMW080620ZTR)(JC5040)Below 250HB20025043.53201,60028.543001,30023.143001,10017.13.52601,50034.22201,10025.122090018 300 3 300 1,100 14.7 3 220 900 15.4 100 3 350 1,700 22.9 3 300 1,700 29.3 Mold steel XDMT080620ZER(-ML) JC7560 150 3 320 1,350 18.2 3 260 1,250 21.6 HPM7, PX5, KPM30 (XDMT080620ZER) (JC5118)(1.2311, P20)(XDMW080620ZTR)(JC5040)30-36HRC20025032.53001,05014.233001,00011.22.522022090015.570010.1 300 2.5 300 1,000 11.2 2.5 220 700 10.1 100 3 300 1,500 21.6 3 250 1,400 25.8 Mold steel 150 3 250 1,100 15.8 3 200 1,000 18.4 NAK80, HPM1(1.2311, P21)38-43HRCXDMT080620ZER(XDMT080620ZER)JC5118(JC8015)20025032.5200200750 10.8 36007.22.5150150 600 11.15007.7 300 2.5 200 600 7.2 2.5 150 500 7.7 100 3 350 1,700 22.9 3 300 1,700 29.3 Die steel 150 3SKD61, SKD11XDMT080620ZER(-ML)JC7560(1.2344, 1.2379)(XDMW080620ZTR)(JC5040)Below 255HB20025032.53201,35018.233001,05014.233001,00011.22.52601,25021.622090015.522070010.1 300 2.5 300 1,000 11.2 2.5 220 700 10.1 Hardened die steel 100 2.5 200 550 9.5 2.5 170 550 12.2 SKD61, DAC, DHA XDMW080620ZTR JC5118 150 2.5 150 400 6.9 2.5 150 500 11.1 (1.2344, 1.2379) (XDMW080620ZTR) (JC8015) 200 2.5 125 260 4.5 2.5 120 300 6.7 40-50HRC 250 2 125 260 3.6 2 120 280 5 100 5 350 2,450 39 5 280 2,250 45.9 Grey cast ironFC250, FC300XDMW080620ZTR JC8015(GG25, GG30)(XDMW080635ZTR-S)(JC8015)15020055Below 300HB25043202,2003552801,80028.752801,40017.842602,10042.82201,70034.72201,40022.8 300 3.5 280 1,400 15.6 3.5 220 1,400 20 100 4 300 1,700 31.9 4 250 1,500 36.1 Nodular cast ironFCD500, FCD700(GGG50, GGG70)Below 300HBXDMW080620ZTR(XDMW080620ZTR)(XDMW080635ZTR-S)JC5118(JC8015)(JC8015)1502002504332701,25023.542501,00014.1325080011.332201,20028.918095017.118080014.4 300 2.5 250 800 9.4 2.5 180 800 12 100 4 300 1,000 19.2 4 240 900 22.1 Stainless steel 150 4 250 800 15.4 4 200 750 18.4 SUS304 XDMT080620ZER(-ML) JC7560Below 250HB(XDMT080620ZER)(JC8050)20025043.522022065012.545509.23.5180180600 14.750010.8 300 3 220 500 7.2 3 180 450 8.3 ap: Depth of cut, n: Spindle speed, Vf: Feed speed, Pc: Net power consumption ■ NOTE 1) The cutting parameters to be adjusted according to the machine rigidity or work rigidity. (Above parameter is for BT50 arbor) 2) In case chatter occurrs, recommend to reduce depth of cut or spindle speed and feed speed. 3) Use air blow to flush the chips out. C114 4) We recommend to use XDMW080635ZTR-S JC8015 (negative geometry inserts) for material having sandinclusions and uneven removal stocks.

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском