Общий каталог Dijet 2018 - страница 257

Навигация

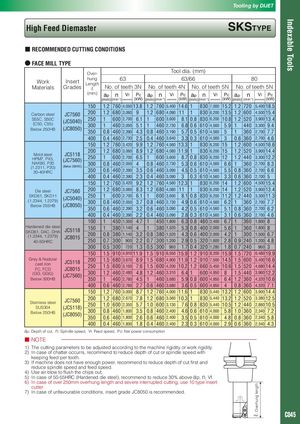

Indexable Tools Tooling by DIJET High Feed Diemaster SKSTyPE ■ RECOMMENDED CUTTING CONDITIONS ● FACE MILL TYPE Over- Tool dia. (mm) WorkMaterials InsertGrades hungLengthℓ 63No. of teeth 3N 63/66No. of teeth 4NNo. of teeth 5N 80No. of teeth 5N (mm) ap n Vf Pc ap n Vf Pc ap n Vf Pc ap n Vf Pc (mm) (min-1) (mm/min) (kW) (mm) (min-1) (mm/min) (kW) (mm) (min-1) (mm/min) (kW) (mm) (min-1) (mm/min) (kW) 150 1.2 760 4,050 13.8 1.2 760 5,400 14.6 1 830 7,000 15.2 1.2 720 5,400 18.5 Carbon steel JC7560 200 1.2 680 3,060 9 1.2 680 4,090 11 1 830 6,200 13.5 1.2 600 4,500 15.4 S55C, S50C(C50, C55)Below 250HB(JC5040)(JC8050)25030035016002,700 6.1 1 600 3,600 8.1 0.8 830 6,200 10.8 1.2 520 3,900 13.414602,0505.114602,7306.80.66104,5605.914403,3009.40.84602,3904.30.84603,1905.70.56104,560513602,7007.7 400 0.4 460 2,730 2.5 0.4 460 3,640 3.3 0.3 610 4,560 3 0.6 360 2,700 4.6 150 1.2 760 3,420 9.9 1.2 760 4,560 13.3 1 830 6,200 15 1.2 600 4,500 16.6 Mold steelHPM7, PX5,NAK80, P20(1.2311, P20)30-40HRCJC5118(JC7560)(Below 36HRC)2002503003501.26803,0608.91.26804,080 11.9 1 830 6,200 15 1.2 520 3,900 14.416002,7006.516003,6008.70.88306,200121.24403,300 12.20.84602,05040.84602,7305.30.66104,5606.613602,7008.30.64602,3903.50.64603,0904.50.56104,5605.50.83602,7006.6 400 0.4 460 2,390 2.3 0.4 460 3,090 3 0.3 610 4,560 3.3 0.6 360 2,700 5 150 1.2 760 3,420 9.2 1.2 760 4,560 12.3 1 830 6,200 14 1.2 600 4,500 15.4 Die steel JC7560 200 1.2 680 3,060 8.3 1.2 680 4,080 11 1 830 6,200 14 1.2 520 3,900 13.4 SKD61, SKD11(1.2344, 1.2379)Below 255HB(JC5040)(JC8050)25030035016002,7006.11600 3,600 8.1 0.8 830 6,200 11.2 1.2 440 3,300 11.30.84602,0503.70.84602,7304.90.66104,5606.213602,7007.70.64602,3903.20.64603,0904.20.56104,5605.10.83602,7006.2 400 0.4 460 2,390 2.2 0.4 460 3,090 2.8 0.3 610 4,560 3.1 0.6 360 2,700 4.6 100 1 450 1,350 4.7 1 450 1,800 6.3 0.8 480 2,400 6.7 1 360 1,800 8 Hardened die steelSKD61, DAC, DHAJC5118(1.2344, 1.2379)JC801540-50HRC15020025013801,140413801,520 5.3 0.8 400 2,000 5.6 1 360 1,800 80.83801,1403.20.83801,5204.30.64002,0004.213001,5006.70.73009002.20.73001,2002.90.53201,6002.80.92401,2004.8 300 0.5 300 720 1.3 0.5 300 960 1.7 0.4 320 1,280 1.8 0.7 240 960 3 150 1.5 910 4,910 11.9 1.5 910 6,550 15.9 1.2 910 8,200 15.9 1.5 720 6,480 19.9 Grey & Nodularcast ironFC, FCD(GG, GGG)Below 300HBJC5118JC8015(JC7560)2002503003501.56803,6708.91.56804,900 11.9 1.2 910 7,500 14.5 1.5 600 5,400 16.61.56003,1507.61.56004,20010.21.2660 5,45010.61.55204,680 14.41.24602,4804.81.24603,3106.4 16004,95081.54403,960 12.214602,7604.514603,6805.90.86004,9506.41.23604,320 10.6 400 0.6 460 2,760 2.7 0.6 460 3,680 3.6 0.5 600 4,950 4 0.8 360 4,320 7.1 150 1,2 760 3,000 8.7 1.2 760 4,000 11.6 1 830 5,440 13.2 1.2 600 3,900 14.4 Stainless steelSUS304Below 250HBJC7560200(JC5118)(JC8050)2503003501,26802.6707.81.26803,560 10.3 1 830 5,440 13.2 1.2 520 3,380 12.51,06002,3505.71.06003,1307.6 0.88305,44010.51.24402,860 10.50.84601,8003.50.84602,4004.60.66104,0005.81.03602,3407.20.64601,8002.60.64602,4003.50.56104,0004.80.83602,3405.8 400 0.4 460 1,800 1.8 0.4 460 2,400 2.3 0.3 610 4,000 2.9 0.6 360 2,340 4.3 ap: Depth of cut, n: Spindle speed, Vf: Feed speed, Pc: Net power consumption ■ NOTE 1) The cutting parameters to be adjusted according to the machine rigidity or work rigidity. 2) In case of chatter occurrs, recommend to reduce depth of cut or spindle speed with keeping feed per tooth. 3) If machine does not have enough power, recommend to reduce depth of cut first and reduce spindle speed and feed speed. 4) Use air blow to flush the chips out. 5) In case of 50-55HRC (Hardened die steel), recommend to reduce 30% above ap, n, Vf. 6) In case of over 250mm overhung length and severe interrupted cutting, use 10 type insert cutter. 7) In case of unfavourable conditions, insert grade JC8050 is recommended. C045 ℓ: Overhung length

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском