Общий каталог Dijet 2018 - страница 241

Навигация

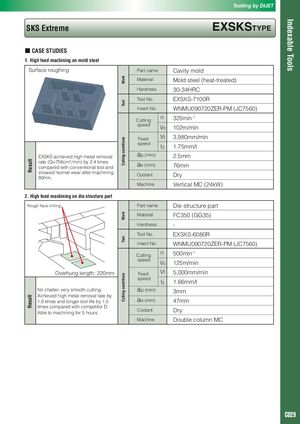

Indexable Tools ResultResult WorkToolCutting conditionsWorkToolCutting conditions Tooling by DIJET SKS Extreme EXSKSTyPE ■ CASE STUDIES 1. High feed machining on mold steel Surface roughing Part name Cavity mold Material Mold steel (heat-treated) Hardness 30-34HRC Tool No. EXSKS-7100R Insert No. WNMU090720ZER-PM (JC7560) Cutting n 325min-1 speed Vc 102m/min Feed Vf 3,980mm/min speed fz 1.75mm/t EXSKS achieved high metal removal ap (mm) 2.5mm rate (Q=756cm3 / min) by 2.4 timescompared with conventional tool andae (mm) 76mm showed normal wear after machining80min. Coolant Dry Machine Vertical MC (24kW) 2. High feed machining on die structure part Rough face milling Part name Die structure part Material FC350 (GG35) Hardness - Tool No. EXSKS-6080R Insert No. WNMU090720ZER-PM (JC7560) Cutting n 500min-1 speed Vc 125m/min Overhung length: 220mm Feed Vf 5,000mm/min speed fz 1.66mm/t No chatter, very smooth cutting.Achieved high metal removal rate by1.9 times and longer tool life by 1.5ap (mm)3mmae (mm)47mm times compared with competitor D.Able to machining for 5 hours. Coolant Dry Machine Double column MC C029

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском