Общий каталог Dijet 2018 - страница 204

Навигация

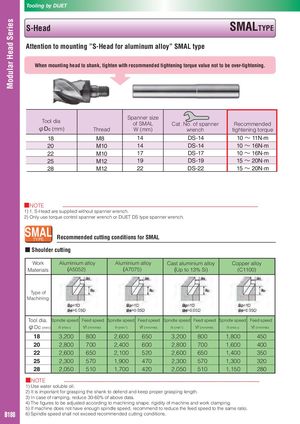

Modular Head Series Tooling by DIJET S-Head SMALTYPE Attention to mounting ”S-Head for aluminum alloy” SMAL type When mounting head to shank, tighten with recommended tightening torque value not to be over-tightening. Tool diaφDc (mm) Spanner sizeof SMAL Cat. No. of spanner RecommendedThreadW (mm)wrenchtightening torque 18 M8 14 DS-14 10 ~ 11N·m 20 M10 14 DS-14 10 ~ 16N·m 22 M10 17 DS-17 10 ~ 16N·m 25 M12 19 DS-19 15 ~ 20N·m 28 M12 22 DS-22 15 ~ 20N·m ■NOTE 1) 1. S-Head are supplied without spanner wrench. 2) Only use torque control spanner wrench or DIJET DS type spanner wrench. SMAL TY PE Recommended cutting conditions for SMAL ■ Shoulder cutting Work Aluminium alloy Aluminium alloy Cast aluminium alloy Copper alloy Materials (A5052) (A7075) (Up to 13% Si) (C1100) Type of Machining Tool dia. Spindle speed Feed speed Spindle speed Feed speed Spindle speed Feed speed Spindle speed Feed speed φDc (mm) n (min-1) Vf (mm/min) n (min-1) Vf (mm/min) n (min-1) Vf (mm/min) n (min-1) Vf (mm/min) 18 3,200 800 2,600 650 3,200 800 1,800 450 20 2,800 700 2,400 600 2,800 700 1,600 400 22 2,600 650 2,100 520 2,600 650 1,400 350 25 2,300 570 1,900 470 2,300 570 1,300 320 28 2,050 510 1,700 420 2,050 510 1,150 280 ■NOTE 1) Use water soluble oil. 2) It is important for grasping the shank to defend and keep proper grasping length. 3) In case of ramping, reduce 30-60% of above data. 4) The figures to be adjusted according to machining shape, rigidity of machine and work clamping. 5) If machine does not have enough spindle speed, recommend to reduce the feed speed to the same ratio. B188 6) Spindle speed shall not exceed recommended cutting conditions.

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском