Общий каталог Dijet 2018 - страница 203

Навигация

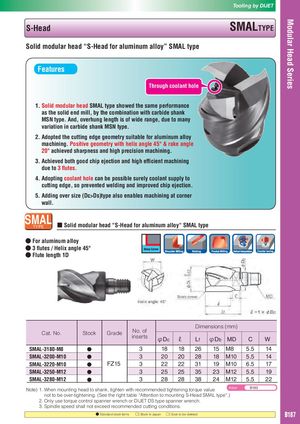

Modular Head Series Tooling by DIJET S-Head SMALTYPE Solid modular head “S-Head for aluminum alloy” SMAL type Features Through coolant hole 1. Solid modular head SMAL type showed the same performance as the solid end mill, by the combination with carbide shank MSN type. And, overhung length is of wide range, due to many variation in carbide shank MSN type. 2. Adopted the cutting edge geometry suitable for aluminum alloy machining. Positive geometry with helix angle 45° & rake angle 20° achieved sharpness and high precision machining. 3. Achieved both good chip ejection and high efficient machining due to 3 flutes. 4. Adopting coolant hole can be possible surely coolant supply to cutting edge, so prevented welding and improved chip ejection. 5. Adding over size (Dc>Ds)type also enables machining at corner wall. SMALTY PE ■ Solid modular head “S-Head for aluminum alloy“ SMAL type ● For aluminum alloy ● 3 flutes / Helix angle 45° ● Flute length 1D Dimensions (mm) Cat. No. Stock Grade No. ofinsertsφDc ℓ Lf φDb MD C W SMAL-3180-M8 ● 3 18 18 26 15 M8 5.5 14 SMAL-3200-M10 ● 3 20 20 28 18 M10 5.5 14 SMAL-3220-M10 ● FZ15 3 22 22 31 19 M10 6.5 17 SMAL-3250-M12 ● 3 25 25 35 23 M12 5.5 19 SMAL-3280-M12 ● 3 28 28 38 24 M12 5.5 22 Note) 1. When mounting head to shank, tighten with recommended tightening torque value Arbor B193 not to be over-tightening. (See the right table “Attention to mounting S-Head SMAL type”.) 2. Only use torque control spanner wrench or DIJET DS type spanner wrench. 3. Spindle speed shall not exceed recommended cutting conditions. ● Standard stock items □: Stock in Japan ○: Soon to be deleted B187

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском