Общий каталог Dijet 2018 - страница 150

Навигация

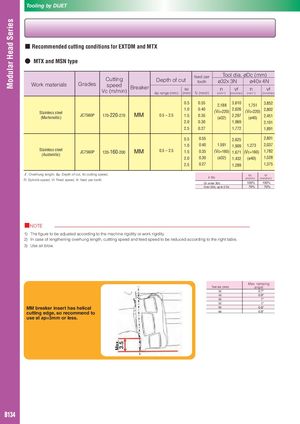

Modular Head Series Max. 3.5 Tooling by DIJET ■ Recommended cutting conditions for EXTDM and MTX ● MTX and MSN type Work materials Grades CuttingspeedVc (m/min)BreakerDepth of cut feed pertoothapap range (mm)(mm)fz (mm/t) Tool dia. øDc (mm)ø32x 3Nø40x 4Nnvfnvf(mm-1)(mm/min)(mm-1)(mm/min) 0.5 0.55 2,188 3,610 1,751 3,852 Stainless steel(Martensitic)JC7560P 170-220-270 MM 1.0 0.40 (Vc=220) 2,626 (Vc=220) 2,8020.5 – 2.51.50.35(ø32)2,297(ø40)2,451 2.0 0.30 1,969 2,101 2.5 0.27 1,772 1,891 0.5 0.55 2,625 2,801 1.0 0.40 1.591 1,909 1,273 2,037 Stainless steel(Austenitic)JC7560P 120-160-200 MM 0.5 – 2.5 1.5 0.35 (Vc=160) 1,671 (Vc=160) 1,782 2.0 0.30 (ø32) 1,432 (ø40) 1,528 2.5 0.27 1,289 1,375 ℓ: Overhung length, ap: Depth of cut, vc:cutting speed,n: Spindle speed, Vf: Feed speed, fz: feed per tooth ℓ/Dc vc vf(m/min)(mm/min) Or under 3Dc 100% 100% Over 3Dc, up to 5 Dc 70% 70% ■NOTE 1) The figure to be adjusted according to the machine rigidity or work rigidity. 2) In case of lengthening overhung length, cuttting speed and feed speed to be reduced according to the right table. 3) Use air blow. Max. ramping Tool dia. (mm) angle 32 0.7° 40 0.8° 50 1° 52 1° MM breaker insert has helical 63 0.8° cutting edge, so recommend to 66 0.8° use at ap=3mm or less. B134

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском