Общий каталог Dijet 2018 - страница 144

Навигация

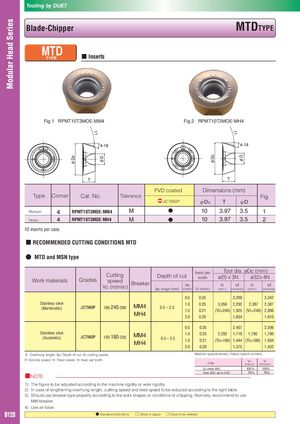

11 11 φDc φD φDc φD Tooling by DIJET Blade-Chipper MTDTYPE MTDTY PE ■ Inserts Fig.1 RPMT10T3MOE-MM4 Fig.2 RPMT10T3MOE-MH4 4-18 4-18 T T PVD coated Dimensions (mm) Type Corner Cat. No. Tolerance Fig. JC7560P φDc T φD Medium 4 RPMT10T3MOE-MM4 M ● 10 3.97 3.5 1 Heavy 4 RPMT10T3MOE-MH4 M ● 10 3.97 3.5 2 10 inserts per case. ■ RECOMMENDED CUTTING CONDITIONS MTD ● MTD and MSN type Work materials Grades CuttingspeedVc (m/min)BreakerDepth of cut feed pertoothapap range (mm)(mm)fz (mm/t) Tool dia. øDc (mm)ø25 x 3Nø32x 4Nnvfnvf(mm-1)(mm/min)(mm-1)(mm/min) 0.5 0.35 3,209 3,342 Stainless steel(Martensitic)JC7560P 190-240-290 MM4MH4 1.0 0.25 3,056 2,292 2,387 2,3870.5 – 2.51.50.21(Vc=240)1,925(Vc=240)2,0062.00.201,8341,910 0.5 0.35 2,407 2,506 Stainless steel(Austenitic)JC7560P 130-180-230 MM4MH4 1.0 0.25 2,292 1,719 1,790 1,7900.5 – 2.51.50.21(Vc=180)1,444(Vc=180)1,504 2.0 0.20 1,375 1,432 ℓ: Overhung length, ap: Depth of cut, vc:cutting speed, Medium type/4corners, Heavy type/4 corners n: Spindle speed, Vf: Feed speed, fz: feed per tooth ℓ/Dc vc vf(m/min)(mm/min) Or under 3DC 100% 100% ■NOTE Over 3DC, up to 5 DC 70% 70% 1) The figure to be adjusted according to the machine rigidity or work rigidity. 2) In case of lengthening overhung length, cuttting speed and feed speed to be reduced according to the right table. 3) Should use breaker type properly according to the work shapes or conditions of chipping. Normally, recommend to use MM-breaker. 4) Use air blow. B128 ● Standard stock items □: Stock in Japan ○: Soon to be deleted

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском