Rh

Rh (Ra)

9

3.0

Tooling by DIJET

QM MAX MQTTYPE

MQT TyPE Definition of flute shape forprogramming MQT TyPE Recommended cutting conditions forMQT

MQT-...A03/A05 Holder MQT Type + MSN Carbide Shank holder

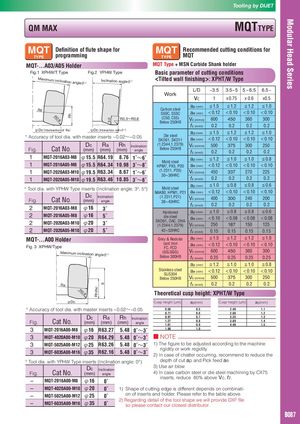

Fig.1 XPHW/T Type Fig.2 YPHW Type Basic parameter of cutting conditions

Maximum inclination angleθ° Inclination angleθ° : XPHT/W Type

L/D ~3.5 3.5~ 5 5 ~ 6.5 6.5 ~

Work Vc 1 x 0.75 x 0.6 x0.5

Ra R0.8 Carbon steel ap (mm) ≦ 1.5 ≦ 1.2 ≦ 1.2 ≦ 1.0S50C, S55Cae (mm)< 0.12< 0.10< 0.10< 0.10R0.3~R0.8(C50, C55)Below 250HBVc (m/min)600450360300

fz (mm/t) 0.2 0.2 0.2 0.2

φDc(Intersection of Ra) φDc(Interection withθ°)° Accuracy of tool dia. with master inserts −0.02~−0.05Die steelSKD61, SKD11ap (mm)≦ 1.5≦ 1.2≦ 1.2≦ 1.0ae (mm)< 0.12< 0.10< 0.10< 0.10

Fig. Cat No. Dc Ra Rh Inclination(mm)(mm)(mm)angle(1.2344,1.2379)Below 255HBVc (m/min)500fz (mm/t)0.23753000.20.22500.2

11 MQT-2016A03-M8 φ15.5 R64.19 8.76 1˚~6˚MQT-2016A05-M8φ15.5 R64.3410.983˚~8˚Mold steelap (mm)≦ 1.2≦ 1.0 ≦ 1.0 ≦ 0.8HPM7, PX5, P20ae (mm)< 0.12< 0.10< 0.10< 0.10

1 MQT-2020A03-M10 φ19.5 R63.34 8.67 1˚~6˚1MQT-2020A05-M10 φ19.5 R63.4610.853˚~8˚(1.2311, P20)30~36HRCVc (m/min)450fz (mm/t)0.23372700.20.22250.2

° Tool dia. with YPHW Type inserts (Inclination angle: 3°、5°)Fig.Cat No.DcInclination(mm)angle2MQT-2016A03-M8φ163˚2MQT-2016A05-M8φ165˚2MQT-2020A03-M10φ203˚Mold steelap (mm)≦ 1.0≦ 0.8≦ 0.8≦ 0.6NAK80, HPM1, P21ae (mm)< 0.12< 0.10< 0.10< 0.10(1.2311,P21)38~43HRCVc (m/min)400fz (mm/t)0.23002400.20.22000.2Hardenedap (mm)≦ 1.0≦ 0.8≦ 0.8≦ 0.6die steelSKD61, DAC, DHAae (mm)< 0.10< 0.08< 0.08< 0.08(1.2344,1.2379)Vc (m/min)250187150125

2 MQT-2020A05-M10 φ20 5˚ 42~52HRC fz (mm/t) 0.15 0.15 0.15 0.15

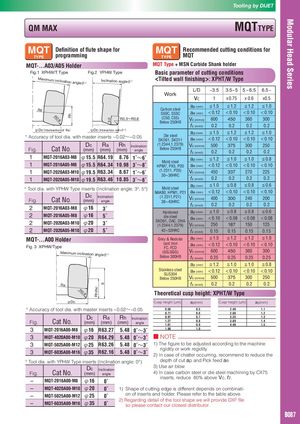

MQT-…A00 Holder Grey & Nodular ap (mm) ≦ 1.5 ≦ 1.2 ≦ 1.2 ≦ 1.0

Fig. 3 XPHW/Type cast ironFC, FCDae (mm) < 0.12 < 0.10 < 0.10 < 0.10

Maximum inclination angleθ° (GG,GGG) Vc (m/min) 600 450 360 300Below 300HBfz (mm/t)0.250.250.250.25

ap (mm) ≦ 1.2 ≦ 1.0 ≦ 1.0 ≦ 0.8

Stainless steelSUS304Below 250HBae (mm)< 0.12< 0.10 < 0.10 < 0.10Vc (m/min)500375300250

Ra fz (mm/t) 0.2 0.2 0.2 0.2

R0.8 Theoretical cusp height: XPHT/W Type

φDc Cusp height (μm) ap(mm) Cusp height (μm) ap(mm)

° Accuracy of tool dia. with master inserts −0.02~−0.05 0.50 0.5 2.40 1.1

0.71 0.6 2.86 1.2

Fig. Cat No. Dc Ra Rh Inclination(mm)(mm)(mm)angle0.971.271.61 0.70.80.9 3.35 1.33.891.44.461.5

3 MQT-2016A00-M8 φ16 R63.27 5.48 0˚~3˚ 1.98 1.0

3 MQT-4020A00-M10 φ20 R64.29 5.48 0˚~3˚ ■ NOTE

3 MQT-5025A00-M12 φ25 R63.26 5.48 0˚~3˚ 1) The figure to be adjusted according to the machine

3 MQT-6035A00-M16 φ35 R62.16 5.48 0˚~3˚ rigidity or work regidity.2) In case of chatter occurring, recommend to reduce the

° Tool dia. with YPHW Type inserts (Inclination angle: 0°) depth of cut ap and Pick feed ae.

Fig. Cat No. Dc Inclination(mm)angle 3) Use air blow.4) In case carbon steel or die steel machining by CX75

– MQT-2016A00-M8 φ16 0˚ inserts, reduce 80% above Vc, fz.

– MQT-4020A00-M10 φ20 0˚ 1) Shape of cutting edge is different depends on combinati-

– MQT-5025A00-M12 φ25 0˚ on of inserts and holder. Please refer to the table above.

– MQT-6035A00-M16 φ35 0˚ 2) Regarding detail of the tool shape we will provide DXF fileso please contact our closest distributor.

B087

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском