Каталог WTO инструмент для обрабатывающих центров - страница 45

Навигация

Operation principle: Sample workpieces Gear hobbing z n c Synchronization of work piece and tool rotation. z n c Feed movement in Z axis. ||Splines e.g. DIN 5480, DIN 5482, TORX When hobbing is finished the hob has to move towards X. Please consider: At the end of the gear/spline there has to be sufficient clearance for the hob. Shifting ||Spur gear n Initial hob position after tool c change with new cutting tool. y n Hob position at end of c cutting tool life. ||Helical gear To optimize the cutting tool life you can move the hob step by step in Y axis direction. This movement enables the usage of all cutting edges of the hob. This procedure is called shifting. © WTO GmbH I Subject to change without notice 3

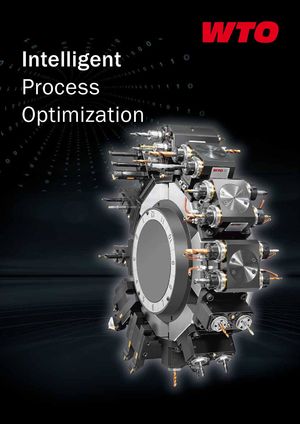

Брошюра WTO обзор решений

Брошюра WTO обзор решений Брошюра WTO обзор решений русский

Брошюра WTO обзор решений русский Каталог WTO инструмент под конкретные обрабатывающие центра

Каталог WTO инструмент под конкретные обрабатывающие центра Каталог WTO инструмент для обрабатывающих центров швейцарского типа

Каталог WTO инструмент для обрабатывающих центров швейцарского типа