Основной каталог Winstar 2021 - страница 276

Навигация

- Cover

- A-Milling

- Solid Carbide Endmills

- H700

- H680

- H650

- H600

- G550

- V470

- G450

- V530

- V520

- M500

- Hypex

- A300

- A200

- A100

- CuttingData

- Milling Inserts

- Indexable Milling Cutters

- Shoulder Milling Cutters

- Face Milling Cutters

- Copy Milling Cutters

- Chamgering & Engraving Cutters

- Helical Milling Cutters

- Disc Milling Cutters

- Modular Milling Tools

- B-Holemaking

- Solid Carbide Drills

- DPC&DPN

- DLC&DLN

- DMC&DMN

- DHN

- DFN

- DZC&DZN

- DAN

- DGN

- CuttingData

- Modular Drills

- Indexable Drills

- Spotting & Centering Drills

- Solid Carbide Reamers

- Indexable Boring Tools

- C-Turning

- ISO Turning Inserts

- Turning Holders

- Parting & Grooving Tools

- Mini Turning Tools for Auto Lathe

- D-Threading

- Solid Thread Mills

- Solid Thread Turning Bars

- Indexable Thread Turning Tools

- E-Customized & Tooling

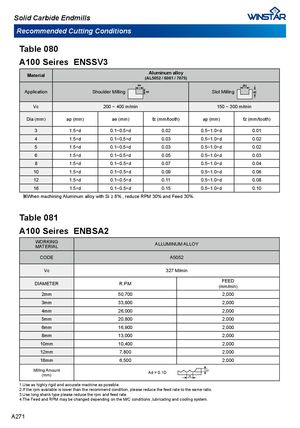

Solid Carbide Endmills Recommended Cutting Conditions Table 080 A100 Seires ENSSV3 Material Aluminum alloy(AL5052 / 6061 / 7075) Application Shoulder Milling Slot Milling Vc 200 ~ 400 m/min 150 ~ 300 m/min Dia (mm) ap (mm) ae (mm) fz (mm/tooth) ap (mm) fz (mm/tooth) 3 1.5×d 0.1~0.5×d 0.02 0.5~1.0×d 0.01 4 1.5×d 0.1~0.5×d 0.03 0.5~1.0×d 0.02 5 1.5×d 0.1~0.5×d 0.03 0.5~1.0×d 0.02 6 1.5×d 0.1~0.5×d 0.05 0.5~1.0×d 0.03 8 1.5×d 0.1~0.5×d 0.07 0.5~1.0×d 0.04 10 1.5×d 0.1~0.5×d 0.09 0.5~1.0×d 0.06 12 1.5×d 0.1~0.5×d 0.11 0.5~1.0×d 0.08 16 1.5×d 0.1~0.5×d 0.15 0.5~1.0×d 0.10 ※When machining Aluminum alloy with Si ≥ 8% , reduce RPM 30% and Feed 30%. Table 081 A100 Seires ENBSA2 WORKINGMATERIAL ALLUMINUM ALLOY CODE A5052 Vc 327 M/min DIAMETER R.P.M FEED(mm/min) 2mm 50,700 2,000 3mm 33,800 2,000 4mm 26,000 2,000 5mm 20,800 2,000 6mm 16,900 2,000 8mm 13,000 2,000 10mm 10,400 2,000 12mm 7,800 2,000 16mm 6,500 2,000 Milling Amount(mm) Ad = 0.1D AdPf 1.Use as highly rigid and accurate machine as possible. 2.If the rpm available is lower than the recommend condition, please reduce the feed rate to the same ratio. 3.Use long shank type please reduce the rpm and feed rate. 4.The Feed and RPM may be changed depending on the M/C conditions ,lubricating and cooling system. A271

Каталог Carbidex сменные пластины 2020

Каталог Carbidex сменные пластины 2020 Каталог Winstar твердосплавные пластины и вставки

Каталог Winstar твердосплавные пластины и вставки Брошюра Winstar пластины 2021

Брошюра Winstar пластины 2021 Каталог Winstar монолитный инструмент 2020

Каталог Winstar монолитный инструмент 2020 Каталог Winstar инструмент со сменными пластинами 2020

Каталог Winstar инструмент со сменными пластинами 2020