Основной каталог Winstar 2021 - страница 263

Навигация

- Cover

- A-Milling

- Solid Carbide Endmills

- H700

- H680

- H650

- H600

- G550

- V470

- G450

- V530

- V520

- M500

- Hypex

- A300

- A200

- A100

- CuttingData

- Milling Inserts

- Indexable Milling Cutters

- Shoulder Milling Cutters

- Face Milling Cutters

- Copy Milling Cutters

- Chamgering & Engraving Cutters

- Helical Milling Cutters

- Disc Milling Cutters

- Modular Milling Tools

- B-Holemaking

- Solid Carbide Drills

- DPC&DPN

- DLC&DLN

- DMC&DMN

- DHN

- DFN

- DZC&DZN

- DAN

- DGN

- CuttingData

- Modular Drills

- Indexable Drills

- Spotting & Centering Drills

- Solid Carbide Reamers

- Indexable Boring Tools

- C-Turning

- ISO Turning Inserts

- Turning Holders

- Parting & Grooving Tools

- Mini Turning Tools for Auto Lathe

- D-Threading

- Solid Thread Mills

- Solid Thread Turning Bars

- Indexable Thread Turning Tools

- E-Customized & Tooling

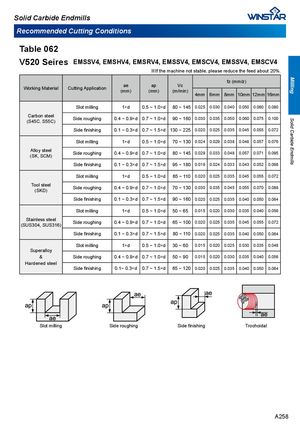

Solid Carbide EndmillsMilling Solid Carbide Endmills Recommended Cutting Conditions Table 062 V520 Seires EMSSV4, EMSHV4, EMSRV4, EMSSV4, EMSCV4, EMSSV4, EMSCV4 ※If the machine not stable, please reduce the feed about 20%. fz (mm/z) Working Material Cutting Application ae(mm) ap Vc(mm)(m/min) 4mm 6mm 8mm 10mm 12mm 16mm Slot milling 1×d 0.5 ~ 1.0×d 80 ~ 145 0.025 0.030 0.040 0.050 0.060 0.080 Carbon steel(S45C, S55C)Side roughing 0.4 ~ 0.9×d 0.7 ~ 1.0×d 90 ~ 160 0.030 0.035 0.050 0.060 0.075 0.100 Side finishing 0.1 ~ 0.3×d 0.7 ~ 1.5×d 130 ~ 225 0.020 0.025 0.035 0.045 0.055 0.072 Slot milling 1×d 0.5 ~ 1.0×d 70 ~ 130 0.024 0.029 0.038 0.048 0.057 0.076 Alloy steel(SK, SCM)Side roughing 0.4 ~ 0.9×d 0.7 ~ 1.0×d 80 ~ 145 0.029 0.033 0.048 0.057 0.071 0.095 Side finishing 0.1 ~ 0.3×d 0.7 ~ 1.5×d 95 ~ 180 0.019 0.024 0.033 0.043 0.052 0.068 Slot milling 1×d 0.5 ~ 1.0×d 65 ~ 110 0.020 0.025 0.035 0.045 0.055 0.072 Tool steel(SKD) Side roughing 0.4 ~ 0.9×d 0.7 ~ 1.0×d 70 ~ 130 0.030 0.035 0.045 0.055 0.070 0.088 Side finishing 0.1 ~ 0.3×d 0.7 ~ 1.5×d 90 ~ 160 0.020 0.025 0.035 0.040 0.050 0.064 Slot milling 1×d 0.5 ~ 1.0×d 50 ~ 65 0.015 0.020 0.030 0.035 0.040 0.056 Stainless steel(SUS304, SUS316)Side roughing0.4 ~ 0.9×d 0.7 ~ 1.0×d 65 ~ 100 0.020 0.025 0.035 0.045 0.055 0.072 Side finishing 0.1 ~ 0.3×d 0.7 ~ 1.5×d 80 ~ 110 0.020 0.025 0.035 0.040 0.050 0.064 Slot milling 1×d 0.5 ~ 1.0×d 30 ~ 60 0.015 0.020 0.025 0.030 0.035 0.048 Superalloy & Side roughing 0.4 ~ 0.9×d 0.7 ~ 1.0×d 50 ~ 90 0.015 0.020 0.030 0.035 0.040 0.056 Hardened steel Side finishing 0.1~ 0.3×d 0.7 ~ 1.5×d 65 ~ 120 0.020 0.025 0.035 0.040 0.050 0.064 Slot milling Side roughing Side finishing Trochoidal A258

Каталог Carbidex сменные пластины 2020

Каталог Carbidex сменные пластины 2020 Каталог Winstar твердосплавные пластины и вставки

Каталог Winstar твердосплавные пластины и вставки Брошюра Winstar пластины 2021

Брошюра Winstar пластины 2021 Каталог Winstar монолитный инструмент 2020

Каталог Winstar монолитный инструмент 2020 Каталог Winstar инструмент со сменными пластинами 2020

Каталог Winstar инструмент со сменными пластинами 2020