Основной каталог Winstar 2021 - страница 221

Навигация

- Cover

- A-Milling

- Solid Carbide Endmills

- H700

- H680

- H650

- H600

- G550

- V470

- G450

- V530

- V520

- M500

- Hypex

- A300

- A200

- A100

- CuttingData

- Milling Inserts

- Indexable Milling Cutters

- Shoulder Milling Cutters

- Face Milling Cutters

- Copy Milling Cutters

- Chamgering & Engraving Cutters

- Helical Milling Cutters

- Disc Milling Cutters

- Modular Milling Tools

- B-Holemaking

- Solid Carbide Drills

- DPC&DPN

- DLC&DLN

- DMC&DMN

- DHN

- DFN

- DZC&DZN

- DAN

- DGN

- CuttingData

- Modular Drills

- Indexable Drills

- Spotting & Centering Drills

- Solid Carbide Reamers

- Indexable Boring Tools

- C-Turning

- ISO Turning Inserts

- Turning Holders

- Parting & Grooving Tools

- Mini Turning Tools for Auto Lathe

- D-Threading

- Solid Thread Mills

- Solid Thread Turning Bars

- Indexable Thread Turning Tools

- E-Customized & Tooling

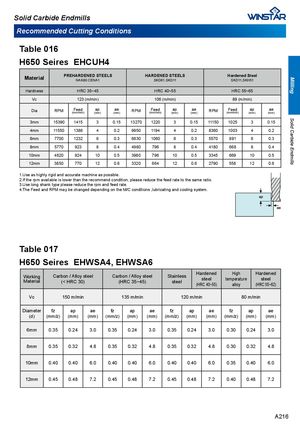

Solid Carbide EndmillsMilling Solid Carbide Endmills Recommended Cutting Conditions Table 016 H650 Seires EHCUH4 Material PREHARDENED STEELSNAK80 CENA1 HARDENED STEELSSKD61,SKD11 Hardened SteelSKD11,SKH51 Hardness HRC 35~45 HRC 40~55 HRC 55~65 Vc 123 (m/min) 106 (m/min) 89 (m/min) Dia RPM Feed (mm/min) ap (mm) ae(mm) RPM Feed (mm/min) ap(mm) ae(mm) RPM Feed (mm/min) ap(mm) ae(mm) 3mm 15390 1415 3 0.15 13270 1220 3 0.15 11150 1025 3 0.15 4mm 11550 1386 4 0.2 9950 1194 4 0.2 8360 1003 4 0.2 6mm 7700 1232 6 0.3 6630 1060 6 0.3 5570 891 6 0.3 8mm 5770 923 8 0.4 4980 796 8 0.4 4180 668 8 0.4 10mm 4620 924 10 0.5 3980 796 10 0.5 3345 669 10 0.5 12mm 3850 770 12 0.6 3320 664 12 0.6 2790 558 12 0.6 1.Use as highly rigid and accurate machine as possible. 2.If the rpm available is lower than the recommend condition, please reduce the feed rate to the same ratio. 3.Use long shank type please reduce the rpm and feed rate. 4.The Feed and RPM may be changed depending on the M/C conditions ,lubricating and cooling system. Table 017 H650 Seires EHWSA4, EHWSA6 Working Carbon / Alloy steelMaterial(< HRC 30) Carbon / Alloy steel(HRC 35~45) Stainlesssteel Hardened High Hardenedsteeltemperaturesteel(HRC 40~55)alloy(HRC 55~62) Vc 150 m/min 135 m/min 120 m/min 80 m/min Diameter fz ap ae fz ap ae fz ap ae fz ap ae (d) (mm/z) (mm) (mm) (mm/z) (mm) (mm) (mm/z) (mm) (mm) (mm/z) (mm) (mm) 6mm 0.35 0.24 3.0 0.35 0.24 3.0 0.35 0.24 3.0 0.30 0.24 3.0 8mm 0.35 0.32 4.8 0.35 0.32 4.8 0.35 0.32 4.8 0.30 0.32 4.8 10mm 0.40 0.40 6.0 0.40 0.40 6.0 0.40 0.40 6.0 0.35 0.40 6.0 12mm 0.45 0.48 7.2 0.45 0.48 7.2 0.45 0.48 7.2 0.40 0.48 7.2 A216

Каталог Carbidex сменные пластины 2020

Каталог Carbidex сменные пластины 2020 Каталог Winstar твердосплавные пластины и вставки

Каталог Winstar твердосплавные пластины и вставки Брошюра Winstar пластины 2021

Брошюра Winstar пластины 2021 Каталог Winstar монолитный инструмент 2020

Каталог Winstar монолитный инструмент 2020 Каталог Winstar инструмент со сменными пластинами 2020

Каталог Winstar инструмент со сменными пластинами 2020