Общий каталог Winstar 2015 - 2016 - страница 66

Навигация

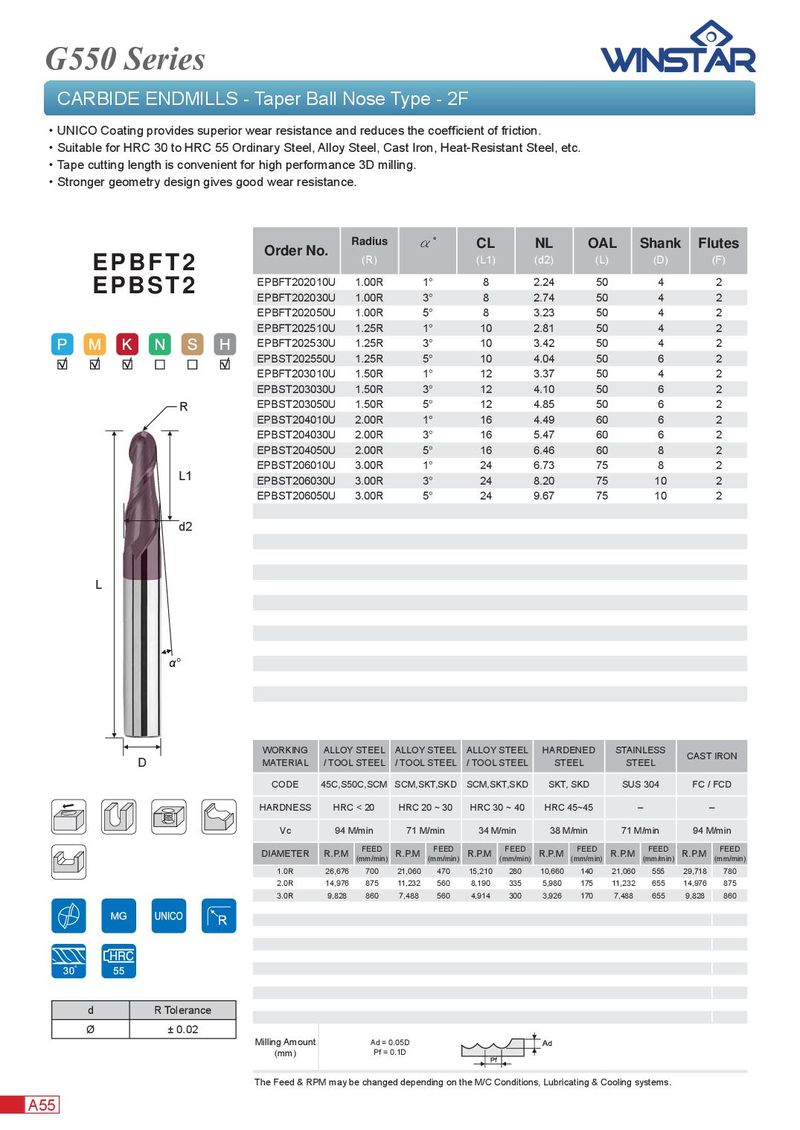

G550 Series CARBIDE ENDMILLS - Taper Ball Nose Type - 2F . UNICO Coating provides superior wear resistance and reduces the coeffi cient of friction. . Suitable for HRC 30 to HRC 55 Ordinary Steel, Alloy Steel, Cast Iron, Heat-Resistant Steel, etc. . Tape cutting length is convenient for high performance 3D milling. . Stronger geometry design gives good wear resistance. Radius α ˚ CL NL OAL Shank Flutes Order No. (R) (L1) (d2) (L) (D) (F) EPBFT2 EPBFT202010U 1.00R 1° 8 2.24 50 4 2 EPBST2 EPBFT202030U 1.00R 3° 8 2.74 50 4 2 EPBFT202050U 1.00R 5° 8 3.23 50 4 2 EPBFT202510U 1.25R 1° 10 2.81 50 4 2 EPBFT202530U 1.25R 3° 10 3.42 50 4 2 EPBST202550U 1.25R 5° 10 4.04 50 6 2 EPBFT203010U 1.50R 1° 12 3.37 50 4 2 EPBST203030U 1.50R 3° 12 4.10 50 6 2 R EPBST203050U 1.50R 5° 12 4.85 50 6 2 EPBST204010U 2.00R 1° 16 4.49 60 6 2 EPBST204030U 2.00R 3° 16 5.47 60 6 2 EPBST204050U 2.00R 5° 16 6.46 60 8 2 EPBST206010U 3.00R 1° 24 6.73 75 8 2 L1 EPBST206030U 3.00R 3° 24 8.20 75 10 2 EPBST206050U 3.00R 5° 24 9.67 75 10 2 d2 L α° WORKING ALLOY STEEL ALLOY STEEL ALLOY STEEL HARDENED STAINLESS CAST IRON D MATERIAL / TOOL STEEL / TOOL STEEL / TOOL STEEL STEEL STEEL CODE 45C,S50C,SCM SCM,SKT,SKD SCM,SKT,SKD SKT, SKD SUS 304 FC / FCD HARDNESS HRC < 20 HRC 20 ~ 30 HRC 30 ~ 40 HRC 45~45 ‒ ‒ Vc 94 M/min 71 M/min 34 M/min 38 M/min 71 M/min 94 M/min FEED FEED FEED FEED FEED FEED DIAMETER R.P.M (mm/min) R.P.M (mm/min) R.P.M (mm/min) R.P.M (mm/min) R.P.M (mm/min) R.P.M (mm/min) 1.0R 26,676 700 21,060 470 15,210 280 10,660 140 21,060 555 29,718 780 2.0R 14,976 875 11,232 560 8,190 335 5,980 175 11,232 655 14,976 875 3.0R 9,828 860 7,488 560 4,914 300 3,926 170 7,488 655 9,828 860 d R Tolerance Ø ± 0.02 Milling Amount Ad = 0.05D (mm) Pf = 0.1D The Feed & RPM may be changed depending on the M/C Conditions, Lubricating & Cooling systems. A55

Каталог Winstar инструмент со сменными пластинами 2020

Каталог Winstar инструмент со сменными пластинами 2020 Каталог Winstar фрезерование

Каталог Winstar фрезерование Каталог Winstar сверление

Каталог Winstar сверление Брошюра Winstar основная номенклатура 2021

Брошюра Winstar основная номенклатура 2021 Основной каталог Winstar 2021

Основной каталог Winstar 2021