Общий каталог Winstar 2015 - 2016 - страница 65

Навигация

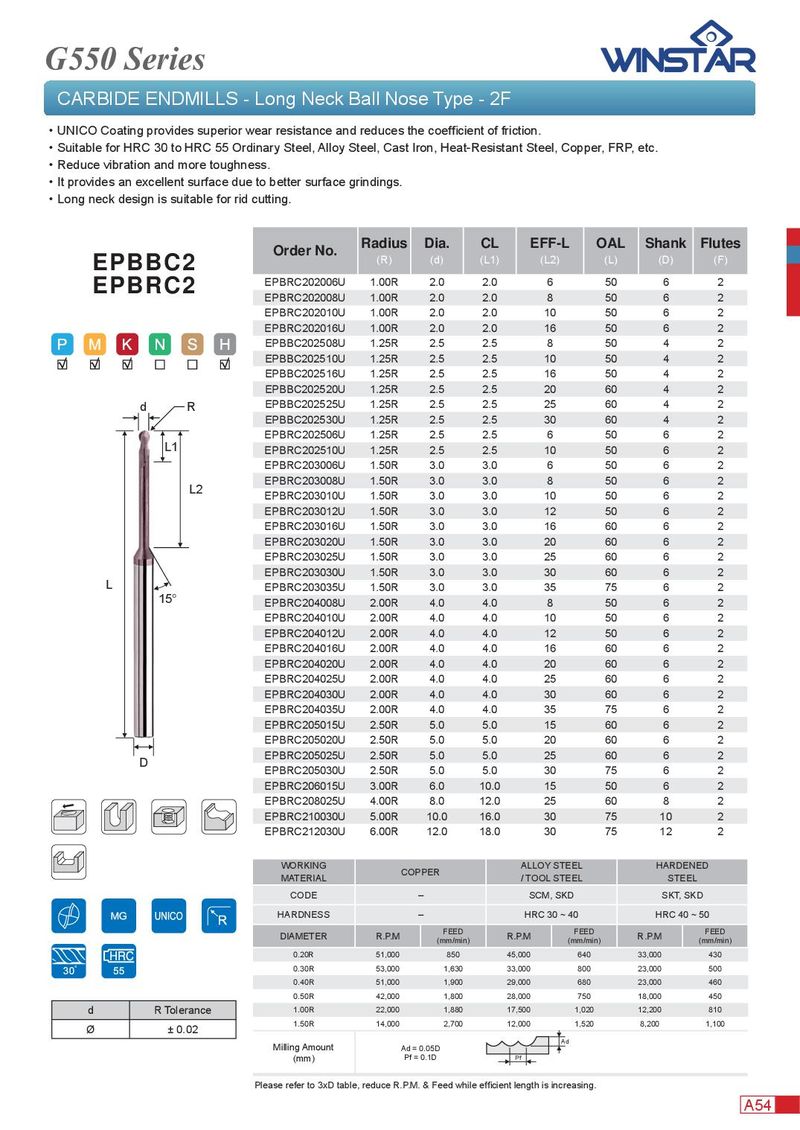

G550 Series CARBIDE ENDMILLS - Long Neck Ball Nose Type - 2F . UNICO Coating provides superior wear resistance and reduces the coeffi cient of friction. . Suitable for HRC 30 to HRC 55 Ordinary Steel, Alloy Steel, Cast Iron, Heat-Resistant Steel, Copper, FRP, etc. . Reduce vibration and more toughness. . It provides an excellent surface due to better surface grindings. . Long neck design is suitable for rid cutting. Radius Dia. CL EFF-L OAL Shank Flutes Order No. (R) (d) (L1) (L2) (L) (D) (F) EPBBC2 EPBRC202006U 1.00R 2.0 2.0 6 50 6 2 EPBRC2 EPBRC202008U 1.00R 2.0 2.0 8 50 6 2 EPBRC202010U 1.00R 2.0 2.0 10 50 6 2 EPBRC202016U 1.00R 2.0 2.0 16 50 6 2 EPBBC202508U 1.25R 2.5 2.5 8 50 4 2 EPBBC202510U 1.25R 2.5 2.5 10 50 4 2 EPBBC202516U 1.25R 2.5 2.5 16 50 4 2 EPBBC202520U 1.25R 2.5 2.5 20 60 4 2 d R EPBBC202525U 1.25R 2.5 2.5 25 60 4 2 EPBBC202530U 1.25R 2.5 2.5 30 60 4 2 EPBRC202506U 1.25R 2.5 2.5 6 50 6 2 L1 EPBRC202510U 1.25R 2.5 2.5 10 50 6 2 EPBRC203006U 1.50R 3.0 3.0 6 50 6 2 EPBRC203008U 1.50R 3.0 3.0 8 50 6 2 L2 EPBRC203010U 1.50R 3.0 3.0 10 50 6 2 EPBRC203012U 1.50R 3.0 3.0 12 50 6 2 EPBRC203016U 1.50R 3.0 3.0 16 60 6 2 EPBRC203020U 1.50R 3.0 3.0 20 60 6 2 EPBRC203025U 1.50R 3.0 3.0 25 60 6 2 EPBRC203030U 1.50R 3.0 3.0 30 60 6 2 L EPBRC203035U 1.50R 3.0 3.0 35 75 6 2 15° EPBRC204008U 2.00R 4.0 4.0 8 50 6 2 EPBRC204010U 2.00R 4.0 4.0 10 50 6 2 EPBRC204012U 2.00R 4.0 4.0 12 50 6 2 EPBRC204016U 2.00R 4.0 4.0 16 60 6 2 EPBRC204020U 2.00R 4.0 4.0 20 60 6 2 EPBRC204025U 2.00R 4.0 4.0 25 60 6 2 EPBRC204030U 2.00R 4.0 4.0 30 60 6 2 EPBRC204035U 2.00R 4.0 4.0 35 75 6 2 EPBRC205015U 2.50R 5.0 5.0 15 60 6 2 EPBRC205020U 2.50R 5.0 5.0 20 60 6 2 EPBRC205025U 2.50R 5.0 5.0 25 60 6 2 D EPBRC205030U 2.50R 5.0 5.0 30 75 6 2 EPBRC206015U 3.00R 6.0 10.0 15 50 6 2 EPBRC208025U 4.00R 8.0 12.0 25 60 8 2 EPBRC210030U 5.00R 10.0 16.0 30 75 10 2 EPBRC212030U 6.00R 12.0 18.0 30 75 12 2 WORKING ALLOY STEEL HARDENED COPPER MATERIAL / TOOL STEEL STEEL CODE ‒ SCM, SKD SKT, SKD HARDNESS ‒ HRC 30 ~ 40 HRC 40 ~ 50 FEED FEED FEED DIAMETER R.P.M (mm/min) R.P.M (mm/min) R.P.M (mm/min) 0.20R 51,000 850 45,000 640 33,000 430 0.30R 53,000 1,630 33,000 800 23,000 500 0.40R 51,000 1,900 29,000 680 23,000 460 0.50R 42,000 1,800 28,000 750 18,000 450 d R Tolerance 1.00R 22,000 1,880 17,500 1,020 12,200 810 1.50R 14,000 2,700 12,000 1,520 8,200 1,100 Ø ± 0.02 Ad Milling Amount Ad = 0.05D (mm) Pf = 0.1D Pf Please refer to 3xD table, reduce R.P.M. & Feed while effi cient length is increasing. A54

Каталог Winstar инструмент со сменными пластинами 2020

Каталог Winstar инструмент со сменными пластинами 2020 Каталог Winstar фрезерование

Каталог Winstar фрезерование Каталог Winstar сверление

Каталог Winstar сверление Брошюра Winstar основная номенклатура 2021

Брошюра Winstar основная номенклатура 2021 Основной каталог Winstar 2021

Основной каталог Winstar 2021