Общий каталог Winstar 2015 - 2016 - страница 54

Навигация

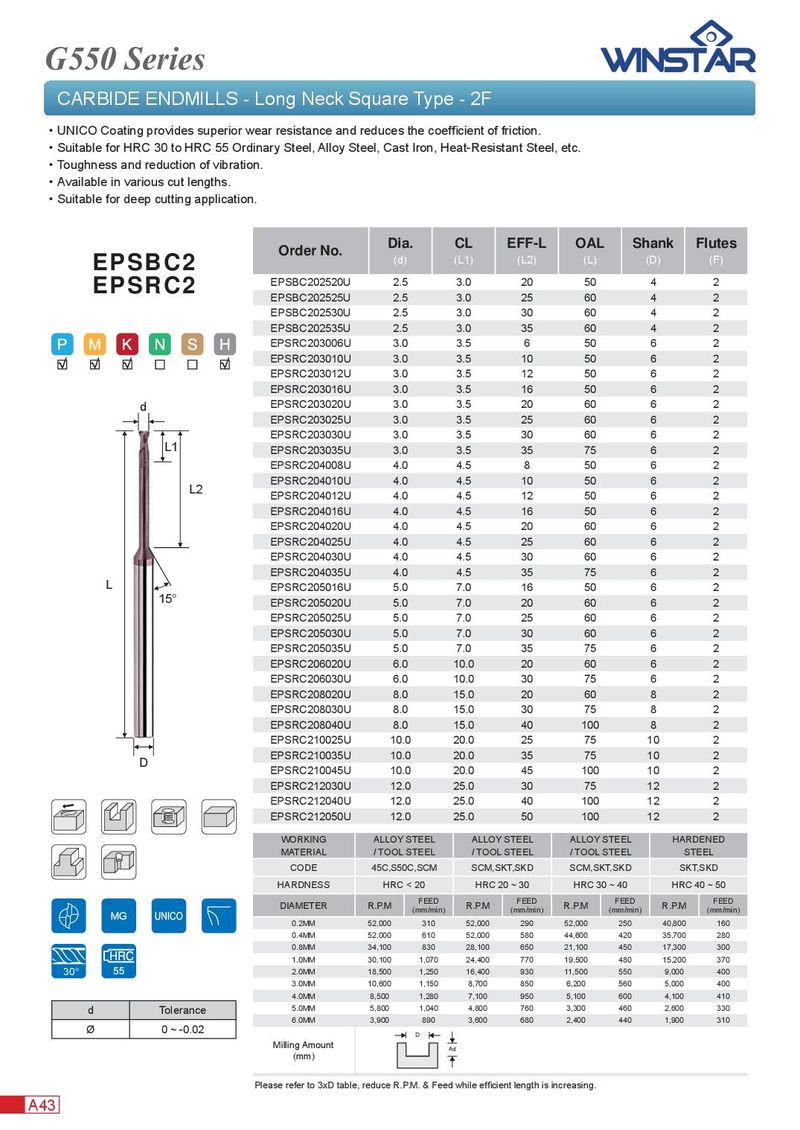

G550 Series CARBIDE ENDMILLS - Long Neck Square Type - 2F . UNICO Coating provides superior wear resistance and reduces the coeffi cient of friction. . Suitable for HRC 30 to HRC 55 Ordinary Steel, Alloy Steel, Cast Iron, Heat-Resistant Steel, etc. . Toughness and reduction of vibration. . Available in various cut lengths. . Suitable for deep cutting application. Dia. CL EFF-L OAL Shank Flutes Order No. (d) (L1) (L2) (L) (D) (F) EPSBC2 EPSBC202520U 2.5 3.0 20 50 4 2 EPSRC2 EPSBC202525U 2.5 3.0 25 60 4 2 EPSBC202530U 2.5 3.0 30 60 4 2 EPSBC202535U 2.5 3.0 35 60 4 2 EPSRC203006U 3.0 3.5 6 50 6 2 EPSRC203010U 3.0 3.5 10 50 6 2 EPSRC203012U 3.0 3.5 12 50 6 2 EPSRC203016U 3.0 3.5 16 50 6 2 d EPSRC203020U 3.0 3.5 20 60 6 2 EPSRC203025U 3.0 3.5 25 60 6 2 EPSRC203030U 3.0 3.5 30 60 6 2 L1 EPSRC203035U 3.0 3.5 35 75 6 2 EPSRC204008U 4.0 4.5 8 50 6 2 EPSRC204010U 4.0 4.5 10 50 6 2 L2 EPSRC204012U 4.0 4.5 12 50 6 2 EPSRC204016U 4.0 4.5 16 50 6 2 EPSRC204020U 4.0 4.5 20 60 6 2 EPSRC204025U 4.0 4.5 25 60 6 2 EPSRC204030U 4.0 4.5 30 60 6 2 EPSRC204035U 4.0 4.5 35 75 6 2 L EPSRC205016U 5.0 7.0 16 50 6 2 15° EPSRC205020U 5.0 7.0 20 60 6 2 EPSRC205025U 5.0 7.0 25 60 6 2 EPSRC205030U 5.0 7.0 30 60 6 2 EPSRC205035U 5.0 7.0 35 75 6 2 EPSRC206020U 6.0 10.0 20 60 6 2 EPSRC206030U 6.0 10.0 30 75 6 2 EPSRC208020U 8.0 15.0 20 60 8 2 EPSRC208030U 8.0 15.0 30 75 8 2 EPSRC208040U 8.0 15.0 40 100 8 2 EPSRC210025U 10.0 20.0 25 75 10 2 EPSRC210035U 10.0 20.0 35 75 10 2 D EPSRC210045U 10.0 20.0 45 100 10 2 EPSRC212030U 12.0 25.0 30 75 12 2 EPSRC212040U 12.0 25.0 40 100 12 2 EPSRC212050U 12.0 25.0 50 100 12 2 WORKING ALLOY STEEL ALLOY STEEL ALLOY STEEL HARDENED MATERIAL / TOOL STEEL / TOOL STEEL / TOOL STEEL STEEL CODE 45C,S50C,SCM SCM,SKT,SKD SCM,SKT,SKD SKT,SKD HARDNESS HRC < 20 HRC 20 ~ 30 HRC 30 ~ 40 HRC 40 ~ 50 FEED FEED FEED FEED DIAMETER R.P.M (mm/min) R.P.M (mm/min) R.P.M (mm/min) R.P.M (mm/min) 0.2MM 52,000 310 52,000 290 52,000 250 40,800 160 0.4MM 52,000 610 52,000 580 44,600 420 35,700 280 0.8MM 34,100 830 28,100 650 21,100 450 17,300 300 1.0MM 30,100 1,070 24,400 770 19,500 480 15,200 370 30° 2.0MM 18,500 1,250 16,400 930 11,500 550 9,000 400 3.0MM 10,600 1,150 8,700 850 6,200 560 5,000 400 4.0MM 8,500 1,280 7,100 950 5,100 600 4,100 410 d Tolerance 5.0MM 5,800 1,040 4,800 760 3,300 460 2,600 330 6.0MM 3,900 890 3,600 680 2,400 440 1,900 310 Ø 0 ~ -0.02 D Milling Amount Ad (mm) Please refer to 3xD table, reduce R.P.M. & Feed while effi cient length is increasing. A43

Каталог Winstar инструмент со сменными пластинами 2020

Каталог Winstar инструмент со сменными пластинами 2020 Каталог Winstar фрезерование

Каталог Winstar фрезерование Каталог Winstar сверление

Каталог Winstar сверление Брошюра Winstar основная номенклатура 2021

Брошюра Winstar основная номенклатура 2021 Основной каталог Winstar 2021

Основной каталог Winstar 2021