Общий каталог Winstar 2015 - 2016 - страница 51

Навигация

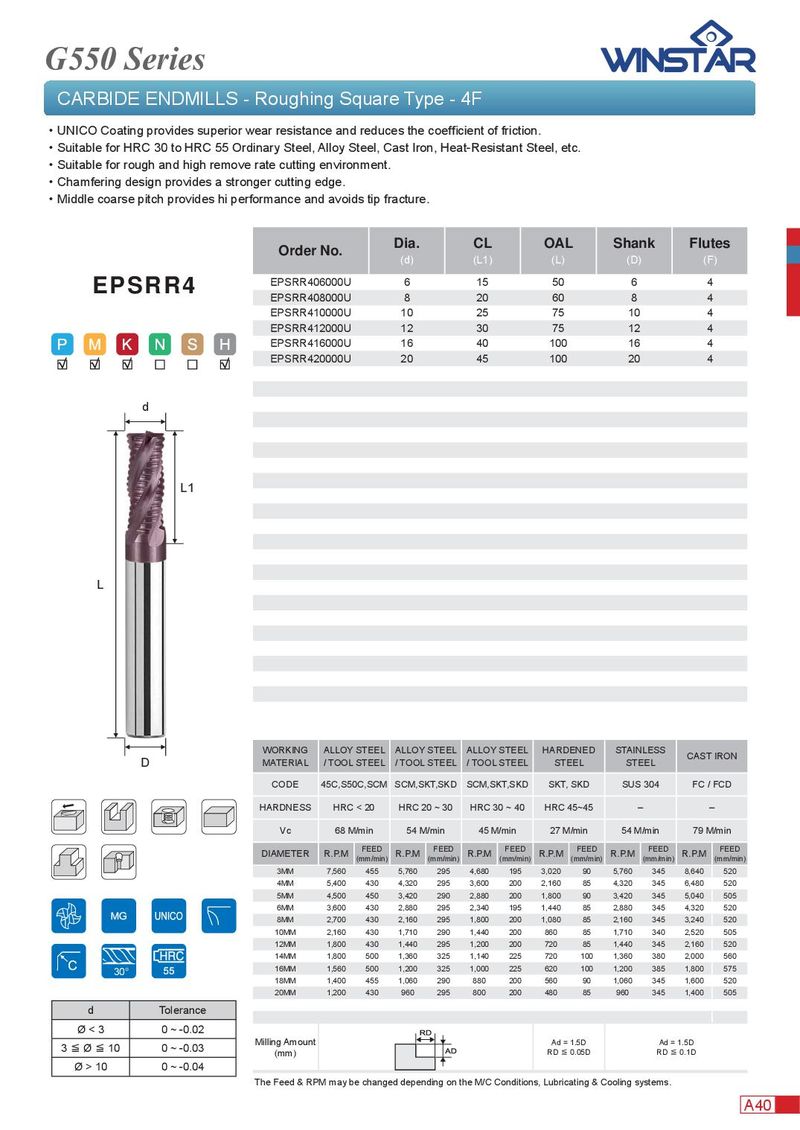

G550 Series CARBIDE ENDMILLS - Roughing Square Type - 4F . UNICO Coating provides superior wear resistance and reduces the coeffi cient of friction. . Suitable for HRC 30 to HRC 55 Ordinary Steel, Alloy Steel, Cast Iron, Heat-Resistant Steel, etc. . Suitable for rough and high remove rate cutting environment. . Chamfering design provides a stronger cutting edge. . Middle coarse pitch provides hi performance and avoids tip fracture. Dia. CL OAL Shank Flutes Order No. (d) (L1) (L) (D) (F) EPSRR406000U 6 15 50 6 4 EPSRR4 EPSRR408000U 8 20 60 8 4 EPSRR410000U 10 25 75 10 4 EPSRR412000U 12 30 75 12 4 EPSRR416000U 16 40 100 16 4 EPSRR420000U 20 45 100 20 4 d L1 L WORKING ALLOY STEEL ALLOY STEEL ALLOY STEEL HARDENED STAINLESS CAST IRON D MATERIAL / TOOL STEEL / TOOL STEEL / TOOL STEEL STEEL STEEL CODE 45C,S50C,SCM SCM,SKT,SKD SCM,SKT,SKD SKT, SKD SUS 304 FC / FCD HARDNESS HRC < 20 HRC 20 ~ 30 HRC 30 ~ 40 HRC 45~45 ‒ ‒ Vc 68 M/min 54 M/min 45 M/min 27 M/min 54 M/min 79 M/min FEED FEED FEED FEED FEED FEED DIAMETER R.P.M (mm/min) R.P.M (mm/min) R.P.M (mm/min) R.P.M (mm/min) R.P.M (mm/min) R.P.M (mm/min) 3MM 7,560 455 5,760 295 4,680 195 3,020 90 5,760 345 8,640 520 4MM 5,400 430 4,320 295 3,600 200 2,160 85 4,320 345 6,480 520 5MM 4,500 450 3,420 290 2,880 200 1,800 90 3,420 345 5,040 505 6MM 3,600 430 2,880 295 2,340 195 1,440 85 2,880 345 4,320 520 8MM 2,700 430 2,160 295 1,800 200 1,080 85 2,160 345 3,240 520 10MM 2,160 430 1,710 290 1,440 200 860 85 1,710 340 2,520 505 12MM 1,800 430 1,440 295 1,200 200 720 85 1,440 345 2,160 520 14MM 1,800 500 1,360 325 1,140 225 720 100 1,360 380 2,000 560 30° 16MM 1,560 500 1,200 325 1,000 225 620 100 1,200 385 1,800 575 18MM 1,400 455 1,060 290 880 200 560 90 1,060 345 1,600 520 20MM 1,200 430 960 295 800 200 480 85 960 345 1,400 505 d Tolerance Ø < 3 0 ~ -0.02 Milling Amount Ad = 1.5D Ad = 1.5D 3 ≦ Ø ≦ 10 0 ~ -0.03 (mm) RD ≦ 0.05D RD ≦ 0.1D Ø > 10 0 ~ -0.04 The Feed & RPM may be changed depending on the M/C Conditions, Lubricating & Cooling systems. A40

Каталог Winstar инструмент со сменными пластинами 2020

Каталог Winstar инструмент со сменными пластинами 2020 Каталог Winstar фрезерование

Каталог Winstar фрезерование Каталог Winstar сверление

Каталог Winstar сверление Брошюра Winstar основная номенклатура 2021

Брошюра Winstar основная номенклатура 2021 Основной каталог Winstar 2021

Основной каталог Winstar 2021