Общий каталог Winstar 2015 - 2016 - страница 33

Навигация

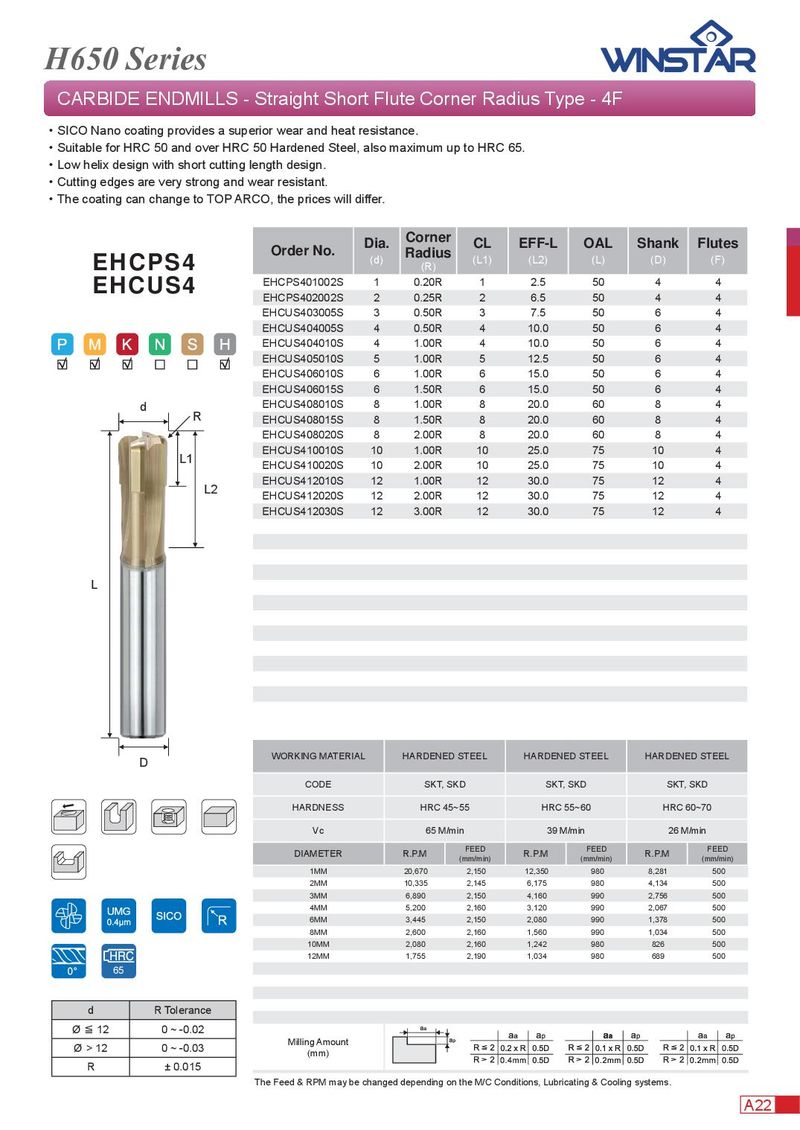

H650 Series CARBIDE ENDMILLS - Straight Short Flute Corner Radius Type - 4F . SICO Nano coating provides a superior wear and heat resistance. . Suitable for HRC 50 and over HRC 50 Hardened Steel, also maximum up to HRC 65. . Low helix design with short cutting length design. . Cutting edges are very strong and wear resistant. . The coating can change to TOP ARCO, the prices will differ. Corner Dia. CL EFF-L OAL Shank Flutes Order No. Radius (d) (L1) (L2) (L) (D) (F) EHCPS4 (R) EHCPS401002S 1 0.20R 1 2.5 50 4 4 EHCUS4 EHCPS402002S 2 0.25R 2 6.5 50 4 4 EHCUS403005S 3 0.50R 3 7.5 50 6 4 EHCUS404005S 4 0.50R 4 10.0 50 6 4 EHCUS404010S 4 1.00R 4 10.0 50 6 4 EHCUS405010S 5 1.00R 5 12.5 50 6 4 EHCUS406010S 6 1.00R 6 15.0 50 6 4 EHCUS406015S 6 1.50R 6 15.0 50 6 4 d EHCUS408010S 8 1.00R 8 20.0 60 8 4 R EHCUS408015S 8 1.50R 8 20.0 60 8 4 EHCUS408020S 8 2.00R 8 20.0 60 8 4 EHCUS410010S 10 1.00R 10 25.0 75 10 4 L1 EHCUS410020S 10 2.00R 10 25.0 75 10 4 EHCUS412010S 12 1.00R 12 30.0 75 12 4 L2 EHCUS412020S 12 2.00R 12 30.0 75 12 4 EHCUS412030S 12 3.00R 12 30.0 75 12 4 L WORKING MATERIAL HARDENED STEEL HARDENED STEEL HARDENED STEEL D CODE SKT, SKD SKT, SKD SKT, SKD HARDNESS HRC 45~55 HRC 55~60 HRC 60~70 Vc 65 M/min 39 M/min 26 M/min FEED FEED FEED DIAMETER R.P.M (mm/min) R.P.M (mm/min) R.P.M (mm/min) 1MM 20,670 2,150 12,350 980 8,281 500 2MM 10,335 2,145 6,175 980 4,134 500 3MM 6,890 2,150 4,160 990 2,756 500 4MM 5,200 2,160 3,120 990 2,067 500 6MM 3,445 2,150 2,080 990 1,378 500 8MM 2,600 2,160 1,560 990 1,034 500 10MM 2,080 2,160 1,242 980 826 500 12MM 1,755 2,190 1,034 980 689 500 65 d R Tolerance Ø ≦ 12 0 ~ -0.02 Milling Amount Ø > 12 0 ~ -0.03 (mm) R ± 0.015 The Feed & RPM may be changed depending on the M/C Conditions, Lubricating & Cooling systems. A22

Каталог Winstar инструмент со сменными пластинами 2020

Каталог Winstar инструмент со сменными пластинами 2020 Каталог Winstar фрезерование

Каталог Winstar фрезерование Каталог Winstar сверление

Каталог Winstar сверление Брошюра Winstar основная номенклатура 2021

Брошюра Winstar основная номенклатура 2021 Основной каталог Winstar 2021

Основной каталог Winstar 2021