Общий каталог Winstar 2015 - 2016 - страница 13

Навигация

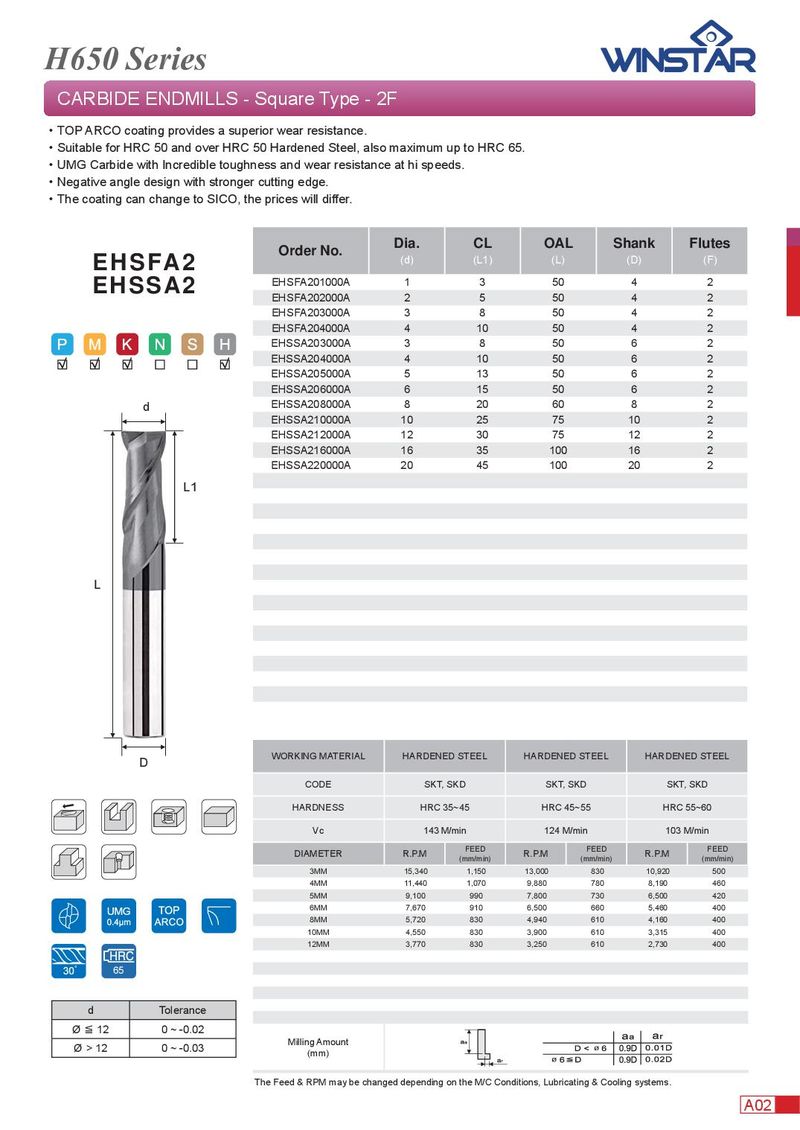

H650 Series CARBIDE ENDMILLS - Square Type - 2F . TOP ARCO coating provides a superior wear resistance. . Suitable for HRC 50 and over HRC 50 Hardened Steel, also maximum up to HRC 65. . UMG Carbide with Incredible toughness and wear resistance at hi speeds. . Negative angle design with stronger cutting edge. . The coating can change to SICO, the prices will differ. Dia. CL OAL Shank Flutes Order No. (d) (L1) (L) (D) (F) EHSFA2 EHSFA201000A 1 3 50 4 2 EHSSA2 EHSFA202000A 2 5 50 4 2 EHSFA203000A 3 8 50 4 2 EHSFA204000A 4 10 50 4 2 EHSSA203000A 3 8 50 6 2 EHSSA204000A 4 10 50 6 2 EHSSA205000A 5 13 50 6 2 EHSSA206000A 6 15 50 6 2 d EHSSA208000A 8 20 60 8 2 EHSSA210000A 10 25 75 10 2 EHSSA212000A 12 30 75 12 2 EHSSA216000A 16 35 100 16 2 EHSSA220000A 20 45 100 20 2 L1 L WORKING MATERIAL HARDENED STEEL HARDENED STEEL HARDENED STEEL D CODE SKT, SKD SKT, SKD SKT, SKD HARDNESS HRC 35~45 HRC 45~55 HRC 55~60 Vc 143 M/min 124 M/min 103 M/min FEED FEED FEED DIAMETER R.P.M (mm/min) R.P.M (mm/min) R.P.M (mm/min) 3MM 15,340 1,150 13,000 830 10,920 500 4MM 11,440 1,070 9,880 780 8,190 460 5MM 9,100 990 7,800 730 6,500 420 6MM 7,670 910 6,500 660 5,460 400 8MM 5,720 830 4,940 610 4,160 400 10MM 4,550 830 3,900 610 3,315 400 12MM 3,770 830 3,250 610 2,730 400 65 d Tolerance Ø ≦ 12 0 ~ -0.02 Milling Amount Ø > 12 0 ~ -0.03 (mm) The Feed & RPM may be changed depending on the M/C Conditions, Lubricating & Cooling systems. A02

Каталог Winstar инструмент со сменными пластинами 2020

Каталог Winstar инструмент со сменными пластинами 2020 Каталог Winstar фрезерование

Каталог Winstar фрезерование Каталог Winstar сверление

Каталог Winstar сверление Брошюра Winstar основная номенклатура 2021

Брошюра Winstar основная номенклатура 2021 Основной каталог Winstar 2021

Основной каталог Winstar 2021