Общий каталог Winstar 2015 - 2016 - страница 12

Навигация

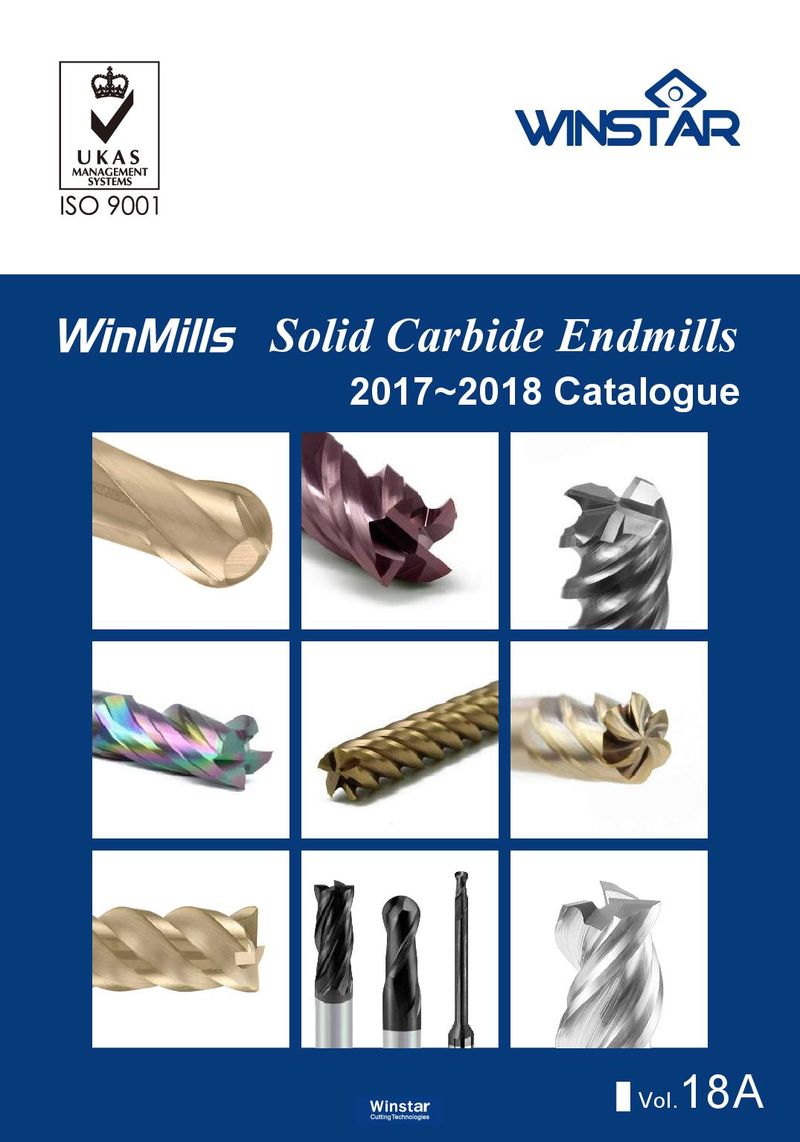

series H650 up to HRC 60 Benefi ts of High-Helix Suitable for HRC50 and over HRC50 Hardened Steel, also for preheated steels, HRC35 and over HRC35. Thick coating is wear resistance and it provides very high tool life. Tool Deflection is reduced because the transferred stresses are vertically thru the spindle rather than horizontal. Speeds chip removal because chip evacuation is vertical. You have more cutting-edge in side cutting. High-Helix end mills increases tool life in side milling Greater shearing action results in increased speeds and feeds and faster stock removal. Horsepower consumption will be decreased with greater shearing action. Inherent to the production of Hi-Helix End Mills is a much thicker core resulting in a much stronger tool. Benefi ts of Low-Helix Less Aggressive, and high rigidity which mean better performance in 3D surface milling. Stronger cutting edge Tools for Hardened Materials. A01

Каталог Winstar инструмент со сменными пластинами 2020

Каталог Winstar инструмент со сменными пластинами 2020 Каталог Winstar фрезерование

Каталог Winstar фрезерование Каталог Winstar сверление

Каталог Winstar сверление Брошюра Winstar основная номенклатура 2021

Брошюра Winstar основная номенклатура 2021 Основной каталог Winstar 2021

Основной каталог Winstar 2021