Общий каталог Winstar 2015 - 2016 - страница 102

Навигация

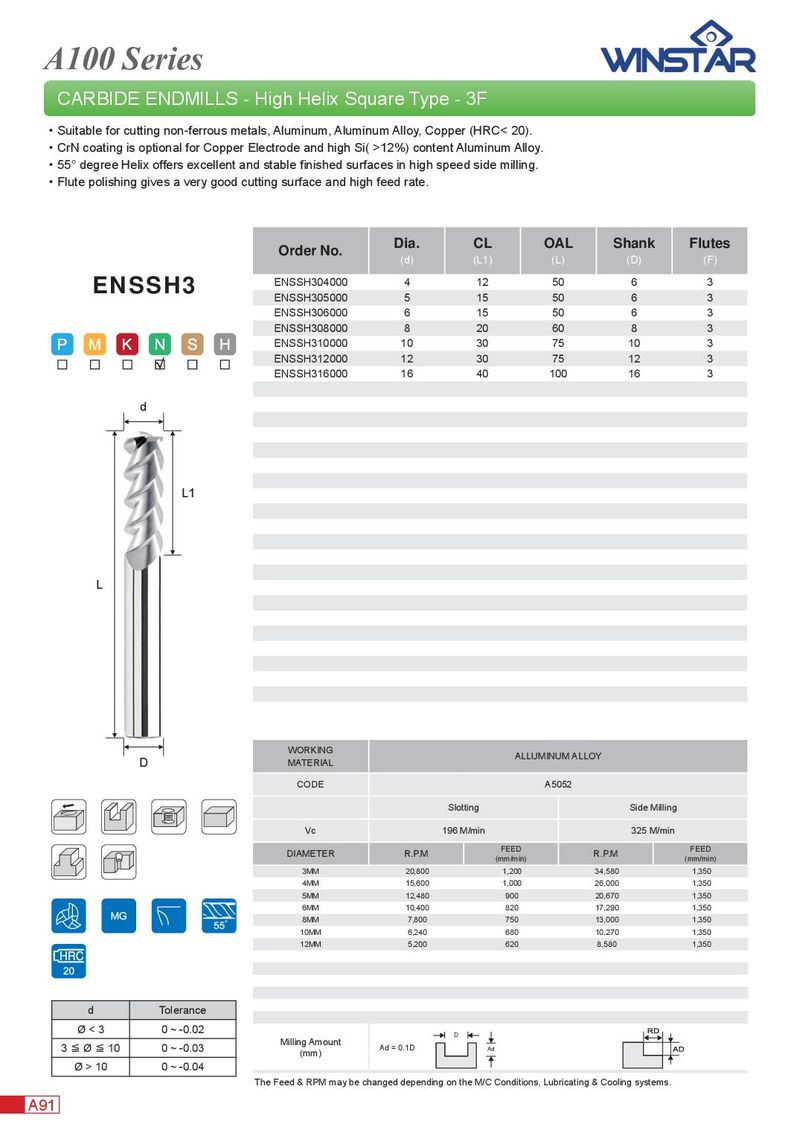

A100 Series CARBIDE ENDMILLS - High Helix Square Type - 3F . Suitable for cutting non-ferrous metals, Aluminum, Aluminum Alloy, Copper (HRC< 20). . CrN coating is optional for Copper Electrode and high Si( >12%) content Aluminum Alloy. . 55° degree Helix offers excellent and stable fi nished surfaces in high speed side milling. . Flute polishing gives a very good cutting surface and high feed rate. Dia. CL OAL Shank Flutes Order No. (d) (L1) (L) (D) (F) ENSSH304000 4 12 50 6 3 ENSSH3 ENSSH305000 5 15 50 6 3 ENSSH306000 6 15 50 6 3 ENSSH308000 8 20 60 8 3 ENSSH310000 10 30 75 10 3 ENSSH312000 12 30 75 12 3 ENSSH316000 16 40 100 16 3 d L1 L WORKING ALLUMINUM ALLOY D MATERIAL CODE A5052 Slotting Side Milling Vc 196 M/min 325 M/min FEED FEED DIAMETER R.P.M (mm/min) R.P.M (mm/min) 3MM 20,800 1,200 34,580 1,350 4MM 15,600 1,000 26,000 1,350 5MM 12,480 900 20,670 1,350 6MM 10,400 820 17,290 1,350 8MM 7,800 750 13,000 1,350 10MM 6,240 680 10,270 1,350 12MM 5,200 620 8,580 1,350 d Tolerance Ø < 3 0 ~ -0.02 D Milling Amount 3 ≦ Ø ≦ 10 0 ~ -0.03 Ad = 0.1D Ad (mm) Ø > 10 0 ~ -0.04 The Feed & RPM may be changed depending on the M/C Conditions, Lubricating & Cooling systems. A91

Каталог Winstar инструмент со сменными пластинами 2020

Каталог Winstar инструмент со сменными пластинами 2020 Каталог Winstar фрезерование

Каталог Winstar фрезерование Каталог Winstar сверление

Каталог Winstar сверление Брошюра Winstar основная номенклатура 2021

Брошюра Winstar основная номенклатура 2021 Основной каталог Winstar 2021

Основной каталог Winstar 2021