Каталог Winstar сверление - страница 111

Навигация

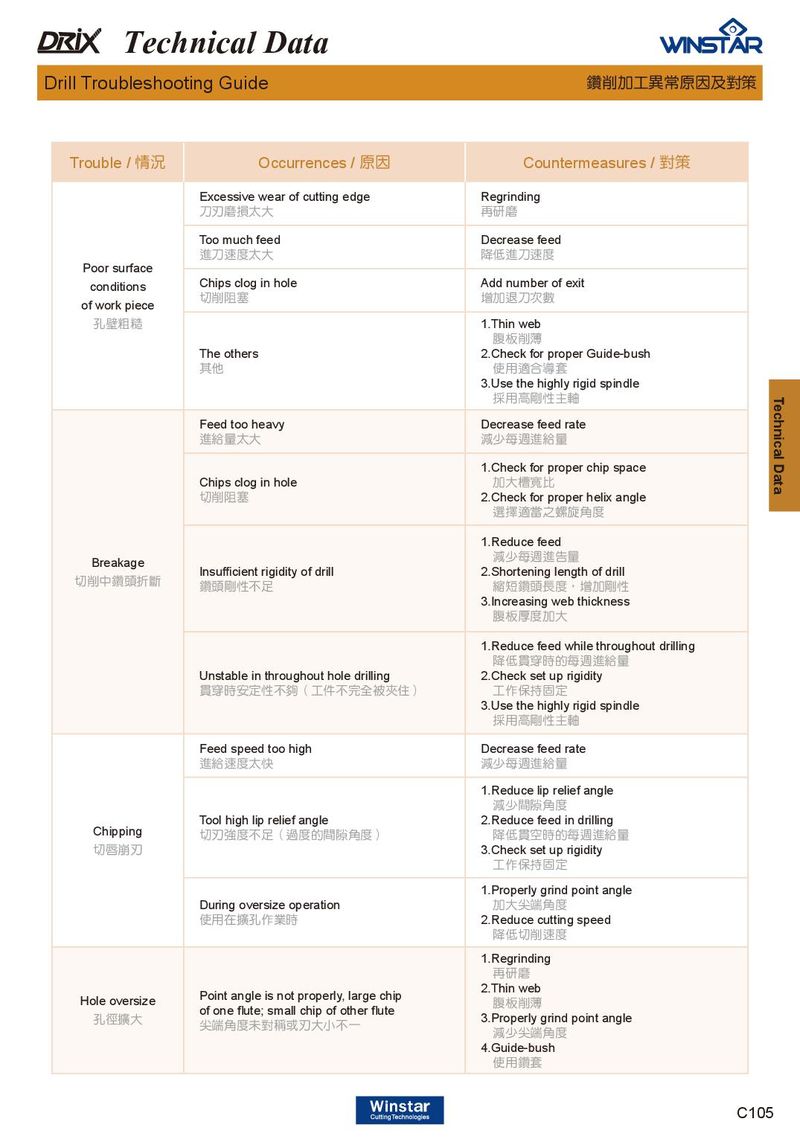

Technical Data Drill Troubleshooting Guide 鑽削加工異常原因及對策 Trouble / 情況 Occurrences / 原因 Countermeasures / 對策 Excessive wear of cutting edge Regrinding 刀刃磨損太大 再研磨 Too much feed Decrease feed 進刀速度太大 降低進刀速度 Poor surface conditions Chips clog in hole Add number of exit 切削阻塞 增加退刀次數 of work piece 孔壁粗糙 1.Thin web 腹板削薄 The others 2.Check for proper Guide-bush 其他 使用適合導套 3.Use the highly rigid spindle Technical Data 採用高剛性主軸 Feed too heavy Decrease feed rate 進給量太大 減少每週進給量 1.Check for proper chip space Chips clog in hole 加大槽寬比 切削阻塞 2.Check for proper helix angle 選擇適當之螺旋角度 1.Reduce feed 減少每週進告量 Breakage Insufficient rigidity of drill 2.Shortening length of drill 切削中鑽頭折斷 鑽頭剛性不足 縮短鑽頭長度,增加剛性 3.Increasing web thickness 腹板厚度加大 1.Reduce feed while throughout drilling 降低貫穿時的每週進給量 Unstable in throughout hole drilling 2.Check set up rigidity 貫穿時安定性不夠 ( 工件不完全被夾住 ) 工作保持固定 3.Use the highly rigid spindle 採用高剛性主軸 Feed speed too high Decrease feed rate 進給速度太快 減少每週進給量 1.Reduce lip relief angle 減少間隙角度 Tool high lip relief angle 2.Reduce feed in drilling Chipping 切刃強度不足 ( 過度的間隙角度 ) 降低貫空時的每週進給量 切唇崩刃 3.Check set up rigidity 工作保持固定 1.Properly grind point angle During oversize operation 加大尖端角度 使用在擴孔作業時 2.Reduce cutting speed 降低切削速度 1.Regrinding 再研磨 2.Thin web Point angle is not properly, large chip Hole oversize 腹板削薄 of one flute; small chip of other flute 孔徑擴大 3.Properly grind point angle 尖端角度未對稱或刃大小不一 減少尖端角度 4.Guide-bush 使用鑽套 C105

Каталог Winstar инструмент со сменными пластинами 2020

Каталог Winstar инструмент со сменными пластинами 2020 Брошюра Winstar основная номенклатура 2021

Брошюра Winstar основная номенклатура 2021 Основной каталог Winstar 2021

Основной каталог Winstar 2021 Общий каталог Winstar 2015 - 2016

Общий каталог Winstar 2015 - 2016 Брошюра Winstar пластины 2021

Брошюра Winstar пластины 2021 Каталог Winstar твердосплавные пластины и вставки

Каталог Winstar твердосплавные пластины и вставки