Каталог Winstar сверление - страница 110

Навигация

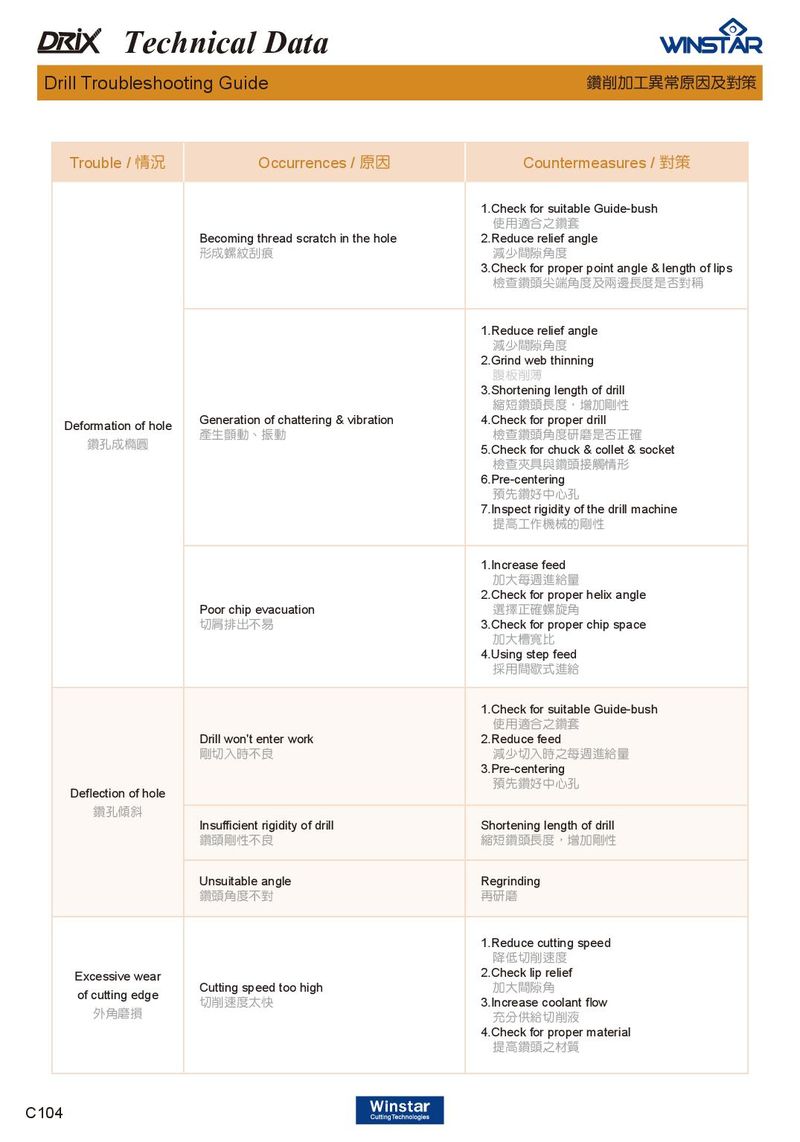

Technical Data Drill Troubleshooting Guide 鑽削加工異常原因及對策 Trouble / 情況 Occurrences / 原因 Countermeasures / 對策 1.Check for suitable Guide-bush 使用適合之鑽套 Becoming thread scratch in the hole 2.Reduce relief angle 形成螺紋刮痕 減少間隙角度 3.Check for proper point angle & length of lips 檢查鑽頭尖端角度及兩邊長度是否對稱 1.Reduce relief angle 減少間隙角度 2.Grind web thinning 腹板削薄 3.Shortening length of drill 縮短鑽頭長度,增加剛性 Generation of chattering & vibration 4.Check for proper drill Deformation of hole 產生顫動、振動 檢查鑽頭角度研磨是否正確 鑽孔成橢圓 5.Check for chuck & collet & socket 檢查夾具與鑽頭接觸情形 6.Pre-centering 預先鑽好中心孔 7.Inspect rigidity of the drill machine 提高工作機械的剛性 1.Increase feed 加大每週進給量 2.Check for proper helix angle Poor chip evacuation 選擇正確螺旋角 切屑排出不易 3.Check for proper chip space 加大槽寬比 4.Using step feed 採用間歇式進給 1.Check for suitable Guide-bush 使用適合之鑽套 Drill won't enter work 2.Reduce feed 剛切入時不良 減少切入時之每週進給量 3.Pre-centering 預先鑽好中心孔 Deflection of hole 鑽孔傾斜 Insufficient rigidity of drill Shortening length of drill 鑽頭剛性不良 縮短鑽頭長度,增加剛性 Unsuitable angle Regrinding 鑽頭角度不對 再研磨 1.Reduce cutting speed 降低切削速度 Excessive wear 2.Check lip relief Cutting speed too high 加大間隙角 of cutting edge 切削速度太快 3.Increase coolant flow 外角磨損 充分供給切削液 4.Check for proper material 提高鑽頭之材質 C104

Каталог Winstar инструмент со сменными пластинами 2020

Каталог Winstar инструмент со сменными пластинами 2020 Брошюра Winstar основная номенклатура 2021

Брошюра Winstar основная номенклатура 2021 Основной каталог Winstar 2021

Основной каталог Winstar 2021 Общий каталог Winstar 2015 - 2016

Общий каталог Winstar 2015 - 2016 Брошюра Winstar пластины 2021

Брошюра Winstar пластины 2021 Каталог Winstar твердосплавные пластины и вставки

Каталог Winstar твердосплавные пластины и вставки