Общий каталог Widia 2017 - страница 1644

Навигация

- Table of Contents

- Turning

- Turning • ISO Inserts

- Turning • Tools for External Turning and Internal Boring

- Turning • Tools for External Turning and Internal Boring

- Turning • Tools for Small Hole Boring

- com E1Turning • Grooving and Cut-Off

- Turning • Threading

- Indexable Milling

- Indexable Milling • Face Mills

- Indexable Milling • Chamfer Mills

- Indexable Milling • 90° Shoulder Mills

- Indexable Milling • Helical Mills

- Indexable Milling • Slotting Mills

- Indexable Milling • Copy Mills

- Solid End Milling

- Solid End Milling • High-Performance Solid Carbide End Mills

- Solid End Milling • General Purpose Solid Carbide End Mills

- Solid End Milling • High-Performance High-Speed Steel (HSS-E/PM)

- Solid End Milling • Burs

- Holemaking

- Holemaking • High-Performance Solid Carbide Drills

- Holemaking • Modular Drills

- Holemaking • Indexable Drills

- Holemaking • Modular Drills

- Holemaking • Indexable Drills

- Holemaking • Hole Finishing

- Tapping

- Tapping Portfolio

- Index by Order Number

- Index by Catalogue Number

- Global Contacts

- Informational Icons Guide

- Material Overview • DIN

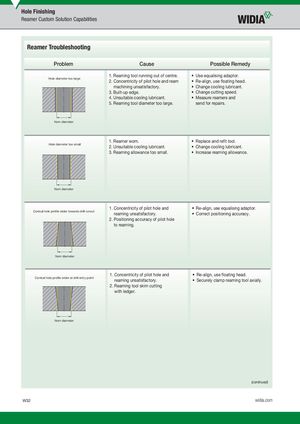

Hole Finishing Reamer Custom Solution Capabilities Reamer Troubleshooting Problem Cause Possible Remedy 1. Reaming tool running out of centre. • Use equalising adaptor. Hole diameter too large 2. Concentricity of pilot hole and ream • Re-align, use floating head. machining unsatisfactory. • Change cooling lubricant. 3. Built-up edge. • Change cutting speed. 4. Unsuitable cooling lubricant. • Measure reamers and 5. Reaming tool diameter too large. send for repairs. Nom diameter 1. Reamer worn. • Replace and refit tool. Hole diameter too small 2. Unsuitable cooling lubricant. • Change cooling lubricant. 3. Reaming allowance too small. • Increase reaming allowance. Nom diameter 1. Concentricity of pilot hole and • Re-align, use equalising adaptor. Conical hole profile wider towards drill runout reaming unsatisfactory. • Correct positioning accuracy. 2. Positioning accuracy of pilot hole to reaming. Nom diameter 1. Concentricity of pilot hole and • Re-align, use floating head. Conical hole profile wider at drill entry point reaming unsatisfactory. • Securely clamp reaming tool axially. 2. Reaming tool skim cutting with ledger. Nom diameter (continued) W32 widia.com

Каталог Widia токарный инструмент 2017

Каталог Widia токарный инструмент 2017 Каталог Widia трохоидальное фрезерование

Каталог Widia трохоидальное фрезерование Каталог Widia техническое руководство по разверткам

Каталог Widia техническое руководство по разверткам Каталог Widia фрезы со сменными пластинами 2016

Каталог Widia фрезы со сменными пластинами 2016 Каталог Widia достижения 2020

Каталог Widia достижения 2020