Каталог Widia достижения 2020 - страница 155

Навигация

- Table of contents

- All-Star

- Indexable Milling

- VSM890™-12

- VXF™

- VXF-07

- VXF-09

- VXF-12

- VXF-16

- VXF Best practices

- Heavy Metal Extensions

- Solid ER Collets

- VSM

- VSM11

- VSM17

- Solid End Milling

- The VariMill Family

- 70NS

- 4U50 & 4U80

- 4U50

- 4U80

- 49N9

- D503

- General Purpose End Mills

- Holemaking

- TDMX

- Top Cut 4

- Turning

- WGC

- WK15CT

- Railway Tooling

- Bar Peeling

- Informational Icons Guide

- Customer Application Support (CAS)

- Material Overview • DIN

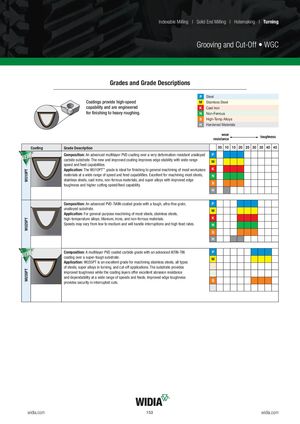

WU10PTWU25PTWU35PT Indexable Milling I Solid End Milling I Holemaking I Turning Grooving and Cut-Off • WGC Grades and Grade Descriptions P Steel Coatings provide high-speed M Stainless Steel capability and are engineered K Cast Iron for finishing to heavy roughing. N Non-Ferrous S High-Temp Alloys H Hardened Materials wearresistance toughness Coating Grade Description 05 10 15 20 25 30 35 40 45 NEW! Composition: An advanced multilayer PVD coating over a very deformation-resistant unalloyed Pcarbide substrate. The new and improved coating improves edge stability with wide rangeM speed and feed capabilities. Application: The WU10PT™ grade is ideal for finishing to general machining of most workpiece K materials at a wide range of speed and feed capabilities. Excellent for machining most steels, N stainless steels, cast irons, non-ferrous materials, and super alloys with improved edge toughness and higher cutting speed/feed capability. S H Composition: An advanced PVD-TiAlN-coated grade with a tough, ultra-fine grain, P unalloyed substrate. M Application: For general-purpose machining of most steels, stainless steels, high-temperature alloys, titanium, irons, and non-ferrous materials. K Speeds may vary from low to medium and will handle interruptions and high feed rates. N S H NEW! Composition: A multilayer PVD coated carbide grade with an advanced AlTiN-TiN Pcoating over a super-tough substrate.M Application: WU35PT is an excellent grade for machining stainless steels, all types of steels, super alloys in turning, and cut-off applications. The substrate provides improved toughness while the coating layers offer excellent abrasion resistance and dependability at a wide range of speeds and feeds. Improved edge toughness provides security in interrupted cuts. S widia.com 153 widia.com

Каталог Widia инструмент для обработки отверстий 2017

Каталог Widia инструмент для обработки отверстий 2017 Каталог Widia токарный инструмент 2020

Каталог Widia токарный инструмент 2020 Каталог Widia монолитный инструмент 2017

Каталог Widia монолитный инструмент 2017 Каталог Widia техническое руководство по разверткам

Каталог Widia техническое руководство по разверткам Каталог Widia инструментальная оснастка

Каталог Widia инструментальная оснастка