Каталог NIKON iNEXIV VMA на английском - страница 9

Навигация

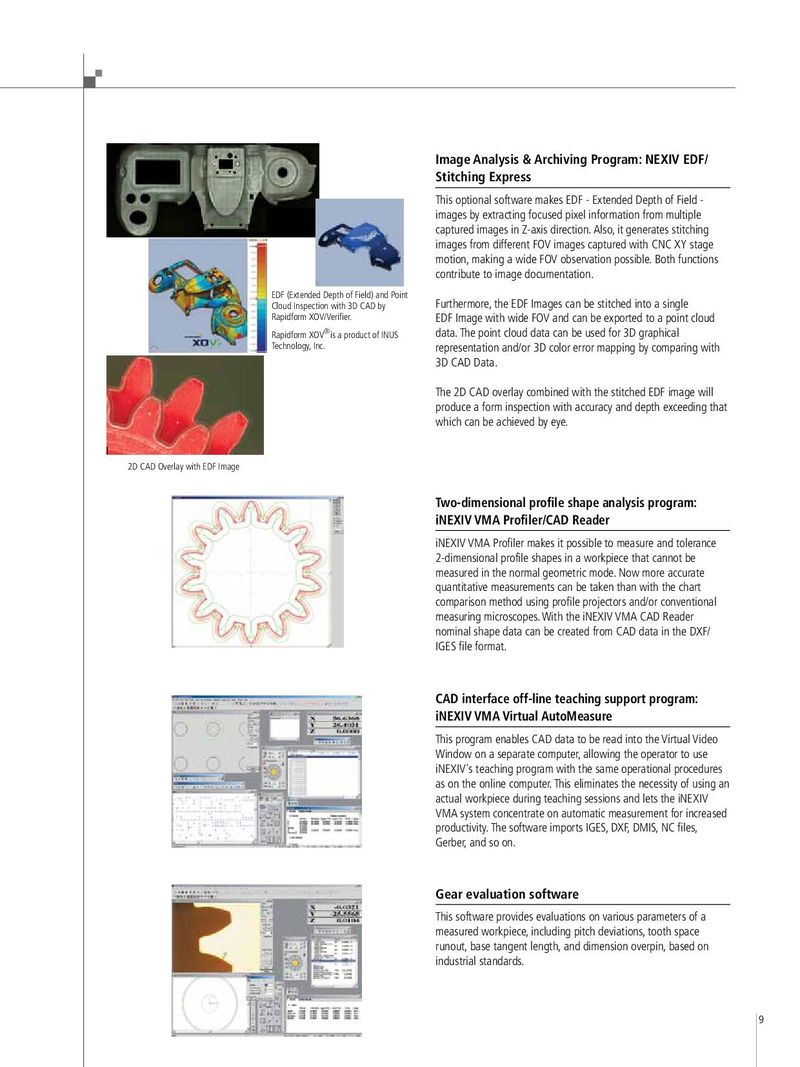

Image Analysis & Archiving Program: NEXIV EDF/ Stitching Express This optional software makes EDF - Extended Depth of Field - images by extracting focused pixel information from multiple captured images in Z-axis direction. Also, it generates stitching images from different FOV images captured with CNC XY stage motion, making a wide FOV observation possible. Both functions contribute to image documentation. EDF (Extended Depth of Field) and Point Furthermore, the EDF Images can be stitched into a single Cloud Inspection with 3D CAD by Rapidform XOV/Verifier. EDF Image with wide FOV and can be exported to a point cloud Rapidform XOV®is a product of INUS data. The point cloud data can be used for 3D graphical Technology, Inc. representation and/or 3D color error mapping by comparing with 3D CAD Data. The 2D CAD overlay combined with the stitched EDF image will produce a form inspection with accuracy and depth exceeding that which can be achieved by eye. 2D CAD Overlay with EDF Image Two-dimensional profile shape analysis program: iNEXIV VMA Profiler/CAD Reader iNEXIV VMA Profiler makes it possible to measure and tolerance 2-dimensional profile shapes in a workpiece that cannot be measured in the normal geometric mode. Now more accurate quantitative measurements can be taken than with the chart comparison method using profile projectors and/or conventional measuring microscopes. With the iNEXIV VMA CAD Reader nominal shape data can be created from CAD data in the DXF/ IGES file format. CAD interface off-line teaching support program: iNEXIV VMA Virtual AutoMeasure This program enables CAD data to be read into the Virtual Video Window on a separate computer, allowing the operator to use iNEXIV's teaching program with the same operational procedures as on the online computer. This eliminates the necessity of using an actual workpiece during teaching sessions and lets the iNEXIV VMA system concentrate on automatic measurement for increased productivity. The software imports IGES, DXF, DMIS, NC files, Gerber, and so on. Gear evaluation software This software provides evaluations on various parameters of a measured workpiece, including pitch deviations, tooth space runout, base tangent length, and dimension overpin, based on industrial standards. 9

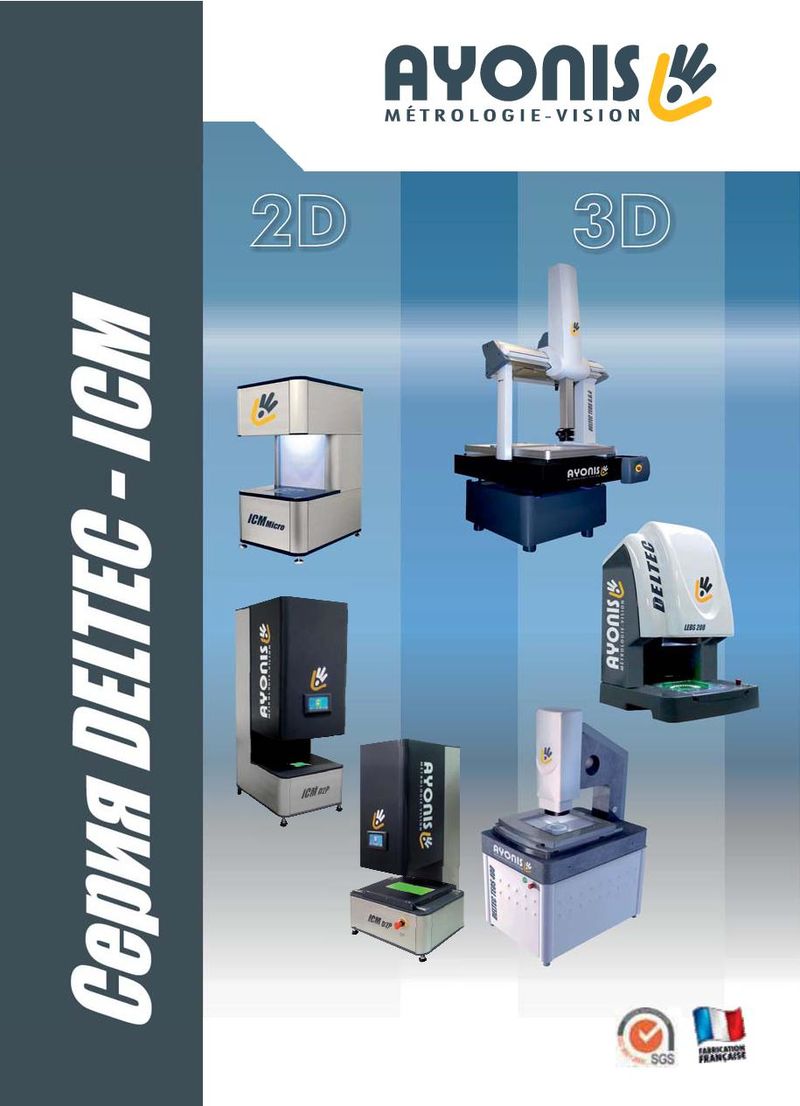

Каталог Ayonis Deltec

Каталог Ayonis Deltec Каталог NIKON iNEXIV VMA

Каталог NIKON iNEXIV VMA