Каталог Tungaloy инструмент для автоматов швейцарского типа - страница 9

Навигация

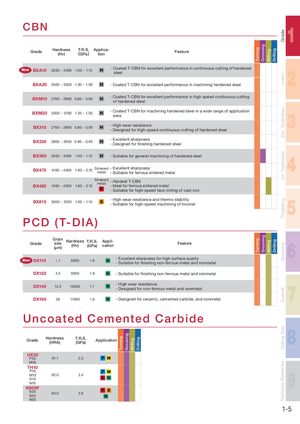

Turning Grooving Milling Drilling TurningTurning GroovingGrooving MillingMilling DrillingDrilling GradeInsertExt. ToolholderInt. ToolholderThreadingGroovingEndmillDrilling ToolTechnical Reference CBN 1 Grade Hardness T.R.S. Applica-(Hv)(GPa)tion Feature New BXA10 3200 ~ 3400 1.00 ~ 1.10 - Coated T-CBN for excellent performance in continuous cutting of hardenedsteelBXA203300 ~ 35001.30 ~ 1.50- Coated T-CBN for excellent performance in machining hardened steel2 BXM10 2700 ~ 2900 0.80 ~ 0.90 - Coated T-CBN for excellent performance in high speed continuous cuttingof hardened steel BXM20 3500 ~ 3700 1.35 ~ 1.50 - Coated T-CBN for machining hardened steel in a wide range of applicationareaBX3102700 ~ 29000.80 ~ 0.90- High wear resistance- Designed for high-speed continuous cutting of hardened steel3 BX330 2800 ~ 3000 0.85 ~ 0.95 - Excellent sharpness- Designed for finishing hardened steel BX360 3200 ~ 3400 1.00 ~ 1.10 - Suitable for general machining of hardened steelBX4704100 ~ 43001.90 ~ 2.10Sinteredmetal- Excellent sharpness- Suitable for ferrous sintered metal 4 BX480 4100 ~ 4300 1.90 ~ 2.10 Sinteredmetal- Hardest T-CBN- Ideal for ferrous sintered metal - Suitable for high-speed face milling of cast iron BX815 3000 ~ 3200 1.00 ~ 1.10 - High wear resistance and thermo stability- Suitable for high-speed machining of Inconel 5 PCD ( T-DIA) Grade Grainsize(µm)Hardness(Hv)T.R.S.(GPa)Appli-cation Feature 6 New DX110 <1 8500 1.8 - Excellent sharpness for high surface quality- Suitable for finishing non-ferrous metal and nonmetal DX120 4.5 9000 1.8 - Suitable for finishing non-ferrous metal and nonmetal DX140 12.5 10000 1.7 - High wear resistance- Designed for non-ferrous metal and nonmetalDX16028110001.6- Designed for ceramic, cemented carbide, and nonmetal 7 Uncoated Cemented Carbide Grade Hardness(HRA) T.R.S.(GPa) Application 8 UX30 P30 91.1 2.3 M30 TH10 P10M10 92.0 2.4K10N10 9 KS05F K05S05 93.0 2.9 N05 1-5

Общий каталог Tungaloy 2020 - 2021

Общий каталог Tungaloy 2020 - 2021 Каталог Tungaloy глубокое сверление 2

Каталог Tungaloy глубокое сверление 2 Каталог Tungaloy зубофрезерование

Каталог Tungaloy зубофрезерование Брошюра Tungaloy новая продукция

Брошюра Tungaloy новая продукция Каталог Tungaloy глубокое сверление 1

Каталог Tungaloy глубокое сверление 1