Каталог Tungaloy инструмент для автоматов швейцарского типа - страница 37

Навигация

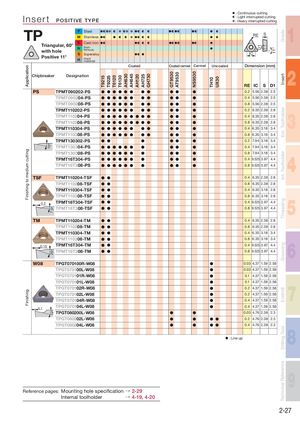

ApplicationFinishing to medium cuttingFinishing 10º7.5º20º14º T9215 T9225 T6120 T6130 AH630 AH645 AH120 AH725 GH730 GT9530 AT9530 NS9530 TH10 UX30 D1 11° GradeInsertExt. ToolholderInt. ToolholderThreadingGroovingEndmillDrilling ToolTechnical Reference C : Continuous cutting Insert POSITIVE TYPE L : Light interrupted cuttingH : Heavy interrupted cutting TP P Steel CL LH L H LH H CL L L CL CL CL C LMStainlessCLCLLHCLLLCLRE S 1 Triangular, 60°with hole KN Cast iron CLNon-ferrousSSuperalloy CL L L CL CL CL CCCLC IC Positive 11° H Hardmaterial Coated Coated cermet Cermet Uncoated Dimension (mm) Chipbreaker Designation 2 RE IC S D1 PS TPMT090202-PS 0.2 5.56 2.38 2.5 TPMT090204-PS 0.4 5.56 2.38 2.5 TPMT090208-PS 0.8 5.56 2.38 2.5 TPMT110202-PS 0.2 6.35 2.38 2.8 TPMT110204-PS TPMT110208-PS 0.4 6.35 2.38 2.80.86.35 2.382.8 3 TPMT110304-PS 0.4 6.35 3.18 3.4 TPMT110308-PS 0.8 6.35 3.18 3.4 TPMT130302-PS 0.2 7.94 3.18 3.4 TPMT130304-PS 0.4 7.94 3.18 3.4 TPMT130308-PS 0.8 7.94 3.18 3.4 TPMT16T304-PS TPMT16T308-PS 0.4 9.525 3.97 4.40.89.525 3.974.4 4 TSF TPMT110204-TSF 0.4 6.35 2.38 2.8 TPMT110208-TSF 0.8 6.35 2.38 2.8 TPMT110304-TSF 0.4 6.35 3.18 2.8 TPMT110308-TSF 0.8 6.35 3.18 2.8 0.2 TPMT16T304-TSF TPMT16T308-TSF 0.4 9.525 3.97 4.40.89.525 3.974.4 5 TM TPMT110204-TM 0.4 6.35 2.38 2.8 TPMT110208-TM 0.8 6.35 2.38 2.8 TPMT110304-TM 0.4 6.35 3.18 3.4 TPMT110308-TM 0.8 6.35 3.18 3.4 0.15 TPMT16T304-TM TPMT16T308-TM 0.4 9.525 3.97 4.40.89.525 3.974.4 6 W08 TPGT070100R-W08 0.03 4.37 1.59 2.58 TPGT070100L-W08 0.03 4.37 1.59 2.58 TPGT070101R-W08 0.1 4.37 1.59 2.58 TPGT070101L-W08 0.1 4.37 1.59 2.58 TPGT070102R-W08TPGT070102L-W08TPGT070104R-W08 0.2 4.37 1.59 2.580.24.371.592.580.44.371.592.587 0.1 TPGT070104L-W08 0.4 4.37 1.59 2.58 TPGT080200L-W08 0.03 4.76 2.38 2.3 TPGT080202L-W08 0.2 4.76 2.38 2.3 TPGT080204L-W08 0.4 4.76 2.38 2.3 䖃㻌: Line up 8 9 Reference pages: Mounting hole specification → 2-29 Internal toolholder → 4-19, 4-20 2-27

Общий каталог Tungaloy 2020 - 2021

Общий каталог Tungaloy 2020 - 2021 Каталог Tungaloy глубокое сверление 2

Каталог Tungaloy глубокое сверление 2 Каталог Tungaloy зубофрезерование

Каталог Tungaloy зубофрезерование Брошюра Tungaloy новая продукция

Брошюра Tungaloy новая продукция Каталог Tungaloy глубокое сверление 1

Каталог Tungaloy глубокое сверление 1