Каталог Tungaloy инструмент для автоматов швейцарского типа - страница 274

Навигация

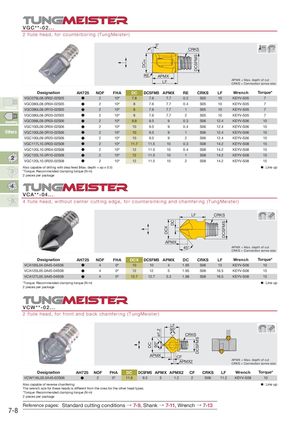

DCh6 DC 90° ø1,2 DCX DC DCSFMSDCSFMS DCSFMS VGC**-02... 2 flute head, for counterboring (TungMeister) 3° CRKS RE APMX LF APMX = Max. depth of cutCRKS = Connection screw size Designation AH725 NOF FHA DC DCSFMS APMX RE CRKS LF Wrench Torque* VGC078L08.0R02-02S05 2 10º 7.8 7.6 7.7 0.2 S05 10 KEYV-S05 7 VGC080L08.0R04-02S05 2 10º 8 7.6 7.7 0.4 S05 10 KEYV-S05 7 Square VGC080L08.0R10-02S05 2 10º 8 7.6 7.7 1 S05 10 KEYV-S05 7 VGC080L08.0R20-02S05 2 10º 8 7.6 7.7 2 S05 10 KEYV-S05 7 chamfering VGC098L09.0R03-02S06 2 10º 9.8 9.5 9 0.3 S06 12.4 KEYV-S06 10 VGC100L09.0R04-02S06 2 10º 10 9.5 9 0.4 S06 12.4 KEYV-S06 10 Others VGC100L09.0R10-02S06 2 10º 10 9.5 9 1 S06 12.4 KEYV-S06 10 VGC100L09.0R20-02S06 2 10º 10 9.5 9 2 S06 12.4 KEYV-S06 10 VGC117L10.0R03-02S08 2 10º 11.7 11.5 10 0.3 S08 14.2 KEYV-S08 15 VGC120L10.0R04-02S08 2 10º 12 11.5 10 0.4 S08 14.2 KEYV-S08 15 VGC120L10.0R10-02S08 2 10º 12 11.5 10 1 S08 14.2 KEYV-S08 15 VGC120L10.0R20-02S08 2 10º 12 11.5 10 2 S08 14.2 KEYV-S08 15 Also capable of drilling with step feed (Max. depth = ap x 0.5) : Line up 3 *Torque: Recommended clamping torque (N∙m) 2 pieces per package 4 VCA**-04... 4 flute head, without center cutting edge, for countersinking and chamfering (TungMeister) LF CRKS APMX 45° APMX = Max. depth of cut CRKS = Connection screw size Designation AH725 NOF FHA DCX DCSFMS APMX DC CRKS LF Wrench Torque* VCA100L04.0A45-04S06 4 0º 10 10 4 1.95 S06 13 KEYV-S06 10 VCA120L05.0A45-04S08 4 0º 12 12 5 1.95 S08 16.5 KEYV-S08 15 VCA127L05.3A45-04S08 4 0º 12.7 12.7 5.3 1.98 S08 16.5 KEYV-S08 15 *Torque: Recommended clamping torque (N∙m) : Line up 2 pieces per package VCW**-02... 2 flute head, for front and back chamfering (TungMeister) LF 90° CRKS APMX CF APMX2 APMX = Max. depth of cutCRKS = Connection screw size Designation AH725 NOF FHA DC DCSFMS APMX APMX2 CF CRKS LF Wrench Torque* VCW118L05.0A45-02S06 2 0º 11.8 9.3 5 1.2 2 S06 11.2 KEYV-S08 10 Also capable of reverse chamfering : Line up The wrench size for these heads is different from the ones for the other head types. *Torque: Recommended clamping torque (N∙m) 2 pieces per package Reference pages: Standard cutting conditions → 7-9, Shank → 7-11, Wrench → 7-13 7-8

Общий каталог Tungaloy 2020 - 2021

Общий каталог Tungaloy 2020 - 2021 Каталог Tungaloy глубокое сверление 2

Каталог Tungaloy глубокое сверление 2 Каталог Tungaloy зубофрезерование

Каталог Tungaloy зубофрезерование Брошюра Tungaloy новая продукция

Брошюра Tungaloy новая продукция Каталог Tungaloy глубокое сверление 1

Каталог Tungaloy глубокое сверление 1