Каталог Tungaloy инструмент для автоматов швейцарского типа - страница 247

Навигация

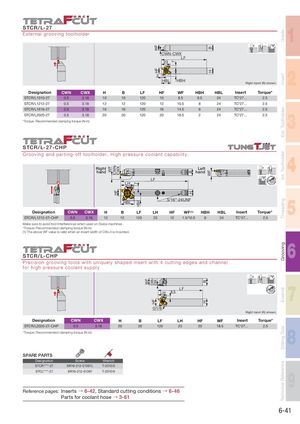

WF CWN-CWXHF 7HBH WF WFHFCWN-CWXHF 7 BH BH BHWF GradeInsertExt. ToolholderInt. ToolholderThreadingGroovingEndmillDrilling ToolTechnical Reference STCR/L-27External grooving toolholder 1 CWN-CWX LF 23 3 HBL HBH Right hand (R) shown. 2 Designation CWN CWX H B LF HF WF HBH HBL Insert Torque* STCR/L1010-27 0.5 3.18 10 10 120 10 8.5 9.5 24 TC*27... 2.5 STCR/L1212-27 0.5 3.18 12 12 120 12 10.5 8 24 TC*27... 2.5 STCR/L1616-27 0.5 3.18 16 16 120 16 14.5 6 24 TC*27... 2.5 STCR/L2020-27 0.5 3.18 20 20 120 20 18.5 2 24 TC*27... 2.5*Torque: Recommended clamping torque (N∙m)3 STCR/L-27-CHP Grooving and parting-off toolholder. High pressure coolant capability. Right Left 4 hand hand LF LH HBL 5/16”-24UNFDesignationCWNCWXHBLFLHHFWF (1)HBHHBLInsertTorque* 5 STCR/L1212-27-CHP 0.5 3.18 12 12 120 23 12 1.5/10.5 8 24 TC*27... 2.5 Make sure to avoid tool interferences when used on Swiss machines *Torque: Recommended clamping torque (N∙m) (1) The above WF value is valid when an insert width of CW=3 is mounted. STCR/L-CHP 6 Precision grooving tools with uniquely shaped insert with 4 cutting edges and channel for high pressure coolant supply LFLH8.5 7 G1/8 Right hand (R) shown. Designation CWN CWX H B LF LH HF WF Insert Torque* STCR/L2020-27-CHP 0.5 3.18 20 20 120 23 20 18.5 TC*27... 2.5 *Torque: Recommended clamping torque (N∙m) 8 SPARE PARTS Designation Screw Wrench STCR****-27 SR16-212-01397L T-2010/5 STCL****-27 SR16-212-01397 T-2010/5 9 Reference pages: Inserts → 6-42, Standard cutting conditions → 6-46 Parts for coolant hose → 3-61 6-41

Общий каталог Tungaloy 2020 - 2021

Общий каталог Tungaloy 2020 - 2021 Каталог Tungaloy глубокое сверление 2

Каталог Tungaloy глубокое сверление 2 Каталог Tungaloy зубофрезерование

Каталог Tungaloy зубофрезерование Брошюра Tungaloy новая продукция

Брошюра Tungaloy новая продукция Каталог Tungaloy глубокое сверление 1

Каталог Tungaloy глубокое сверление 1