Каталог Tungaloy инструмент для автоматов швейцарского типа - страница 203

Навигация

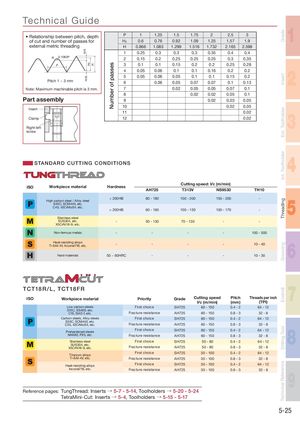

H/4H/8 H2 H Number of passes GradeInsertExt. ToolholderInt. ToolholderThreadingGroovingEndmillDrilling ToolTechnical Reference Te c h n i c a l Guide • Relationship between pitch, depth P 1 1.25 1.5 1.75 2 2.5 3of cut and number of passes forH20.60.760.921.091.251.571.91 external metric threading H 0.866 1.083 1.299 1.516 1.732 2.165 2.598 1 0.25 0.3 0.3 0.3 0.35 0.4 0.4 R 0.1083P 2 0.15 0.2 0.25 0.25 0.25 0.3 0.35 P 3 0.1 0.1 0.15 0.2 0.2 0.25 0.28 Pitch 1 ~ 3 mm 4 0.05 0.06 0.1 0.1 0.16 0.2 0.250.050.060.050.10.10.150.260.060.050.070.070.10.132 Note: Maximum machinable pitch is 3 mm. 7 0.02 0.05 0.05 0.07 0.1 8 0.02 0.02 0.05 0.1 Part assembly 9 0.02 0.03 0.05 Insert 10 0.02 0.05 11Clamp12Right-left 0.020.02 3 screw S TA N D A R D CUTTING CONDITIONS 4 ISO Workpiece material Hardness Cutting speed: Vc (m/min) AH725 T313V NS9530 TH10 High carbon steel / Alloy steel < 200HB 80 - 180 100 - 200 150 - 200S45C, SCM440, etc.C45, 42CrMoS4, etc.> 200HB60 - 160100 - 150100 - 170--5 Stainless steel SUS304, etc. - 50 - 130 70 - 130 - - X5CrNi18-9, etc. Non-ferrous metals - - - - 100 - 500 Heat-resisting alloysTi-6AI-4V, Inconel718, etc. - -Hard materials50 ~ 60HRC--- -- 10 - 4010 - 30 6 TCT18R/L, TCT18FRISO Workpiece material Priority Grade Cutting speed Pitch Threads per inch 7 Vc (m/min) (mm) (TPI) Low carbon steels First choice SH725 60 - 150 0.4 - 2 64 - 12 S15C, SS400, etc. C15, St42-1, etc. Fracture resistance AH725 60 - 150 0.8 - 3 32 - 8 Carbon steels, Alloy steels First choice SH725 60 - 150 0.4 - 2 64 - 12 S55C, SCM440, etc. C55, 42CrMoS4, etc. Fracture resistance AH725 60 - 150 0.8 - 3 32 - 8 Prehardened steelsNAK80, PX5, etc.Stainless steel First choice SH725 60 - 150 0.4 - 2 64 - 12Fracture resistanceAH72560 - 1500.8 - 332 - 8First choiceSH72550 - 800.4 - 264 - 128 SUS304, etc.X5CrNi18-9, etc. Fracture resistance AH725 50 - 80 0.8 - 3 32 - 8 Titanium alloys First choice SH725 30 - 100 0.4 - 2 64 - 12 Ti-6AI-4V, etc. Fracture resistance AH725 30 - 100 0.8 - 3 32 - 8 Heat-resisting alloys First choice SH725 30 - 100 0.4 - 2 64 - 12 Inconel718, etc. Fracture resistance AH725 30 - 100 0.8 - 3 32 - 8 9 Reference pages: TungThread: Inserts → 5-7 - 5-14, Toolholders → 5-20 - 5-24 TetraMini-Cut: Inserts → 5-4, Toolholders → 5-15 - 5-17 5-25

Общий каталог Tungaloy 2020 - 2021

Общий каталог Tungaloy 2020 - 2021 Каталог Tungaloy глубокое сверление 2

Каталог Tungaloy глубокое сверление 2 Каталог Tungaloy зубофрезерование

Каталог Tungaloy зубофрезерование Брошюра Tungaloy новая продукция

Брошюра Tungaloy новая продукция Каталог Tungaloy глубокое сверление 1

Каталог Tungaloy глубокое сверление 1