Каталог Tungaloy инструмент для автоматов швейцарского типа - страница 188

Навигация

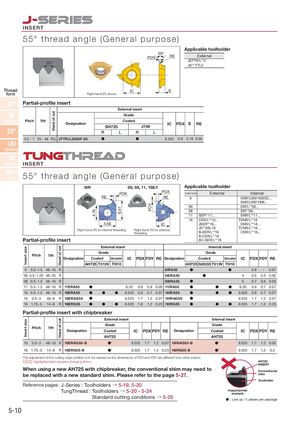

Insert sizeInsert size Hand of cut Hand of cutHand of cut 4.76 6.41 PDY INSERT 55° thread angle (General purpose) Applicable toolholder 55ºPDX RE External 55° JSTTR/L**3JS**-TTL3 Threadform IC SRight hand (R) shown. 60º Partial-profile insert External insert M Grade (Metric) Pitch TPI Designation CoatedSH725 J740 IC PDX S RE 55º R L R L 0.5 - 1 25 - 48 R/L JTTR/L3005F-55 䖃 䖃 9.525 0.6 3.18 0.05 UN (Unified) W (Whitworth) INSERT BSPT(R, PT) 55° thread angle (General purpose) 6IR 06, 08, 11, 16E/I Applicable toolholder PDX PDX Insert size External Internal RE RE 6 SNR/L000*K06SC... 55° SNR/L000*H06...06SIR/L**06... 08 SIR**08... 11 SER**11... SNR/L**11... 16 CER/L**16... TSNR/L**16 5.56 IC JSER**16... SNR/L**16... Right hand (R) for internal threading Right hand (R) for externalthreading JS**SEL16 TCNR/L**16...B-SER/L**16CNR/L**16... B-CER/L**16 Partial-profile insert BC-SER/L**16 External insert Internal insert Grade Grade Pitch TPI Designation Coated Uncoated IC PDX PDY RE Designation Coated Uncoated IC PDX PDY RE AH725 T313V TH10 AH725 GH330 T313V TH10 6 0.5~1.5 48~16 R 6IRA55 䖃 䖃 - 0.9 - 0.07 06 0.5~1.25 48~20 R 06IRA55 䖃 4 0.5 0.5 0.05 08 0.5~1.5 48~16 R 08IRA55 䖃 5 0.7 0.6 0.05 11 0.5~1.5 48~16 R 11ERA55 䖃 6.35 0.9 0.8 0.05 11IRA55 䖃 䖃 䖃 6.35 0.9 0.7 0.07 16 0.5~1.5 48~16 R 16ERA55 䖃 䖃 䖃 9.525 0.9 0.7 0.07 16IRA55 䖃 䖃 䖃 9.525 0.9 0.7 0.07 16 0.5~3 48~8 R 16ERAG55 䖃 9.525 1.7 1.2 0.07 16IRAG55 䖃 9.525 1.7 1.2 0.07 16 1.75~3 14~8 R 16ERG55 䖃 䖃 䖃 9.525 1.6 1.2 0.25 16IRG55 䖃 䖃 䖃 9.525 1.7 1.2 0.25 Partial-profile insert with chipbreaker External insert Internal insert Grade Grade Pitch TPI Designation Coated IC PDX PDY RE Designation Coated IC PDX PDY RE AH725 AH725 16 0.5~3 48~16 R 16ERAG55-B 䖃* 9.525 1.7 1.2 0.07 16IRAG55-B 䖃* 9.525 1.7 1.2 0.05 16 1.75~3 14~8 R 16ERG55-B 䖃* 9.525 1.7 1.2 0.23 16IRG55-B 䖃* 9.525 1.7 1.2 0.2 The adjustment of the cutting edge position w i l l be needed as the dimensions of PDX and PDY are different from other inserts. highlighted item requires changing shims. AH725 INSERT When using a new AH725 with chipbreaker, the conventional shim may need to Conventional be replaced with a new standard shim. Please refer to the page 5-27. shim Toolholder Reference pages: J-Series : Toolholders → 5-19, 5-20 TungThread : Toolholders → 5-20 - 5-24 Inappropriateexample Standard cutting conditions → 5-25 䖃 : Line up / 5 pieces per package 5-10

Общий каталог Tungaloy 2020 - 2021

Общий каталог Tungaloy 2020 - 2021 Каталог Tungaloy глубокое сверление 2

Каталог Tungaloy глубокое сверление 2 Каталог Tungaloy зубофрезерование

Каталог Tungaloy зубофрезерование Брошюра Tungaloy новая продукция

Брошюра Tungaloy новая продукция Каталог Tungaloy глубокое сверление 1

Каталог Tungaloy глубокое сверление 1