Каталог Tungaloy инструмент для автоматов швейцарского типа - страница 156

Навигация

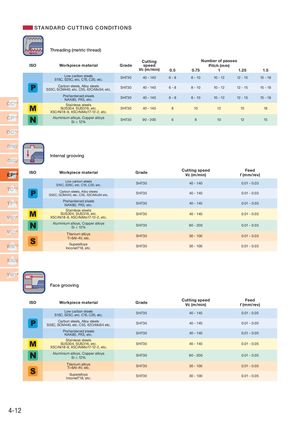

STANDARD CUT TING CONDITIONS Threading (metric thread) Cutting Number of passes ISO Workpiece material Grade speed Pitch (mm) Vc (m/min) 0.5 0.75 1 1.25 1.5 Low carbon steelsS15C, S25C, etc. C15, C20, etc.SH73040 - 140 6-8 8 - 10 10 - 12 12 - 15 15 - 18 Carbon steels, Alloy steelsS55C, SCM440, etc. C55, 42CrMoS4, etc.SH73040 - 1406-8 8 - 10 10 - 12 12 - 15 15 - 18 Prehardened steelsNAK80, PX5, etc. SH730 40 - 140 6-8 8 - 10 10 - 12 12 - 15 15 - 18 CC** Stainless steels SUS304, SUS316, etc. SH730 40 - 140 8 10 12 15 18 X5CrNi18-9, X5CrNiMo17-12-2, etc. CP** Aluminium alloys, Copper alloysSi < 12% SH730 90 - 200 6 8 10 12 15 DC** DPMT Internal grooving DXGU EP** ISO Workpiece material Grade Cutting speed FeedVc (m/min)f (mm/rev) Low carbon steelsS15C, S25C, etc. C15, C20, etc.SH730 40 - 140 0.01 - 0.03 TC** Carbon steels, Alloy steelsS55C, SCM440, etc. C55, 42CrMoS4 etc.SH730 40 - 140 0.01 - 0.03 TP** Prehardened steelsNAK80, PX5, etc. SH730 40 - 140 0.01 - 0.03 Stainless steels SUS304, SUS316, etc. SH730 40 - 140 0.01 - 0.03 VB** X5CrNi18-9, X5CrNiMo17-12-2, etc. Aluminium alloys, Copper alloysSi < 12% SH730 90 - 200 0.01 - 0.03 VC** Titanium alloysTi-6AI-4V, etc. SH730 30 - 100 0.01 - 0.03 WB** SuperalloysInconel718, etc. SH730 30 - 100 0.01 - 0.03 WXGU YW** Face grooving ISO Workpiece material Grade Cutting speed FeedVc (m/min)f (mm/rev) Low carbon steelsS15C, S25C, etc. C15, C20, etc. SH730 40 - 140 0.01 - 0.05 Carbon steels, Alloy steelsS55C, SCM440, etc. C55, 42CrMoS4 etc.SH730 40 - 140 0.01 - 0.05 Prehardened steelsNAK80, PX5, etc. SH730 40 - 140 0.01 - 0.05 Stainless steels SUS304, SUS316, etc. SH730 40 - 140 0.01 - 0.05 X5CrNi18-9, X5CrNiMo17-12-2, etc. Aluminium alloys, Copper alloysSi < 12% SH730 90 - 200 0.01 - 0.05 Titanium alloysTi-6AI-4V, etc. SH730 30 - 100 0.01 - 0.05 SuperalloysInconel718, etc. SH730 30 - 100 0.01 - 0.05 4-12

Общий каталог Tungaloy 2020 - 2021

Общий каталог Tungaloy 2020 - 2021 Каталог Tungaloy глубокое сверление 2

Каталог Tungaloy глубокое сверление 2 Каталог Tungaloy зубофрезерование

Каталог Tungaloy зубофрезерование Брошюра Tungaloy новая продукция

Брошюра Tungaloy новая продукция Каталог Tungaloy глубокое сверление 1

Каталог Tungaloy глубокое сверление 1