Каталог Tungaloy инструмент для автоматов швейцарского типа - страница 107

Навигация

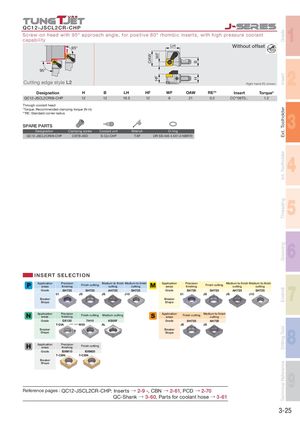

OAW WFHF BH GradeInsertExt. ToolholderInt. ToolholderThreadingGroovingEndmillDrilling ToolTechnical Reference QC12-JSCL2CR-CHPScrew-onheadwith 95° approach angle, for positive 80° rhombic inserts, with high pressure coolantcapability 1 95° LH Without offset 95°Cutting edge style L2 Right hand (R) shown. 2 Designation H B LH HF WF OAW RE** Insert Torque* QC12-JSCL2CR09-CHP 12 12 19.5 12 6 21 0.2 CC**09T3... 1.2 Through-coolant head *Torque: Recommended clamping torque (N∙m) **RE: Standard corner radiusSPARE PARTS 3 Designation Clamping screw Coolant unit Wrench O-ring QC12-JSCL2CR09-CHP CSTB-4SD S-CU-CHP T-8F OR SS-045 4.5X1.0 NBR70 4 5 6 INSERT SELECTION Applicationareas PrecisionfinishingFinish cuttingMedium to finish Medium to finishcuttingcuttingApplicationareasPrecisionfinishingFinish cuttingMedium to finish Medium to finishcuttingcuttingGradeSH725SH725AH725SH725GradeSH725SH725AH725SH72501JSJSJ1001JSJSJ10BreakerBreaker7 Shape Shape Applicationareas PrecisionfinishingFinish cuttingMedium cutting ApplicationareasFinish cutting Medium to finishcutting Grade DX120 TH10 KS05F Grade SH725 AH725 T-DIA with rake W20 AL JS JS BreakerShape BreakerShape 8 Applicationareas PrecisionfinishingFinish cutting Grade BXM10 BXM20 T-CBN T-CBN Breaker Shape 9 Reference pages : QC12-JSCL2CR-CHP: Inserts → 2-9 -, CBN → 2-61, PCD → 2-70 QC-Shank → 3-60, Parts for coolant hose → 3-61 3-25

Общий каталог Tungaloy 2020 - 2021

Общий каталог Tungaloy 2020 - 2021 Каталог Tungaloy глубокое сверление 2

Каталог Tungaloy глубокое сверление 2 Каталог Tungaloy зубофрезерование

Каталог Tungaloy зубофрезерование Брошюра Tungaloy новая продукция

Брошюра Tungaloy новая продукция Каталог Tungaloy глубокое сверление 1

Каталог Tungaloy глубокое сверление 1