Каталог TooTool техническая информация 1 - страница 72

Навигация

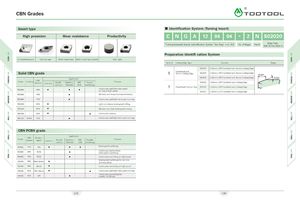

CBN Grades A\ Insert type Identification System (Turning Insert) High presicion Wear resistance Productivity 'A IlHI’ S02020 -< ' *2/ ^ "Turning Indexable Inserts indentification System " See Page =|> 013 No. of Edges Hand Edge Prep.(Ref. To the Table 1)Preparation Identifi cation System for regrinding type One use type Multi-corner type Multi-corner type (coated) Solid type Symbol Cutting Edge Spec. Example Shape S01020 0.10mm x 20°Chamfered and Honed Cutting Edge Solid CBN grade s Chamfered andHoned Cutting EdgeS020200.20mm x 20°Chamfered and Honed Cutting Edge Width Application S02030 0.20mm x 30°Chamfered and Honed Cutting Edge Grade Coating CBNVolumeCast iron Ductilecast ironHardnessMaterialMillPowderRollsmetallurgy Purpose T01020 0.10mm x 20°Chamfered and Cutting Edge TB1000 90% Continuous and light interrupted T Chamfered Cutting Edge T02020 0.20mm x 20°Chamfered and Cutting Edgeturning at high speedT020250.20mm x 25°Chamfered and Cutting Edge TB3000 50% Medium and heavy interrupted turning TB5000 75% Continuous and light interrupted turning TBX200 85% Light to mdeium interrupted milling TBX300 95% Medium and high interrupted turning TBX500 85% Continuous turning TBC500 TiALN 75% Continuous and light interrupted turning CBN PCBN grade Application Grade CBNVolume BindingagentCast iron Ductile Hardness Mill Powder Purpose cast iron Material Rolls metallurgy TB100C 75% TiN Interrupted machining TB300C 60% HCN Continuous and mediuminterrupted machining TB400C 50% TICN Continuous machining at high speed TBX20C 90% New binder Interrupted machining tor cast ironseat ring alloys TBX30C 90% Metal Continuous machining at high speed TBX40C 85% TiN+Metal Continuous and light interrupted turning TBX50C 65% TiN Continuous processing forpowider metallurgy 143 144

Общий каталог TooTool

Общий каталог TooTool Каталог TooTool монолитные фрезы

Каталог TooTool монолитные фрезы Каталог TooTool техническая информация 2

Каталог TooTool техническая информация 2