Каталог TooTool техническая информация 1 - страница 71

Навигация

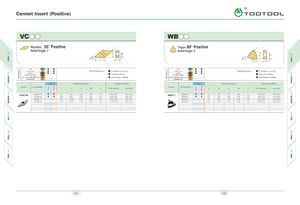

Cermet Insert (Positive) A\ vcoo WBOO Rhombic 35° Positive r Trigon 80° Positive Relief Angle: 7° Relief Angle: 5° -ldl35° \ [iyt Hri Idir Steel p Steel p u Stainless steel M # # Machining types 0 Continuous cuttingCLCast iron-VNon-ferrous metal5*SGeneral cuttingo5Heat resistant alloy, Titaium alloy 4S£ Interrupted cuttingQJStainless steelCast ironMK**SNon-ferrous metalo5Heat resistant alloy, Titaium alloyNS Machining types O Continuous cutting$ General cutting# Interrupted cutting Hardened steel H Hardened steel H Coated Dimensions(mm) Cutting Condition Coated Dimensions(mm) Cutting Condition i in Inserts Designation 8 r i Ir d t dl r fn (mm/rev) ap (mm) Inserts Designation 8 r J£2 I d t dl r fn (mm/rev) ap (mm)i VCMT- PS 110302-PS 10.5 6.35 3.18 2.80 0.2 0.03-0.20 0.20-1.20 WBGT- F 060102L-F 2.6 3.97 1.59 2.30 0.2 0.01-0.05 0.10-0.30 110304-PS 10.0 6.35 3.18 2.80 0.4 0.04-0.20 0.20-1.20 060104L - F 2.5 3.97 1.59 2.30 0.4 0.01-0.10 0.10-0.50 160404-PS 15.6 9.525 4.76 4.40 0.4 0.05 -0.20 0.30-1.50 080202L-F 3.1 4.76 2.38 2.30 0.2 0.01-0.08 0.10-0.40 160408-PS 14.6 9.525 4.76 4.40 0.8 0.10-0.20 0.30-1.50 080204L- F 3.0 4.76 2.38 2.30 0.4 0.01-0.10 0.10-0.50 141 142

Общий каталог TooTool

Общий каталог TooTool Каталог TooTool монолитные фрезы

Каталог TooTool монолитные фрезы Каталог TooTool техническая информация 2

Каталог TooTool техническая информация 2