Каталог TooTool техническая информация 1 - страница 39

Навигация

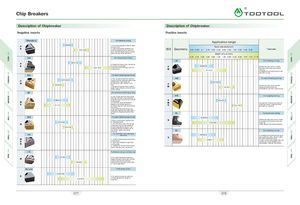

Chip Breakers A\ 0 Description of Chipbreaker Description of Chipbreaker Negative inserts Positive inserts Standard For General cutting Application range P 0.2-0.5 •With broad applied and cast iron. range for steel feed rate (mm/rev ) K - 5.0 15.0 •High cutting edge hardness, lowcutting resistance force, eay chip- ISO Geometry 0.04 0.063 0.1 0.16 0.25 0.40 0.63 1.00 1.60 2.50 4.00 6.30 Features flow. Combined with more abrasive grade can get better efficiency. depth of cut (mm) For Heavy duty cutting 0.10 0.16 0.25 0.40 0.63 1.00 1.60 2.50 4.00 6.30 10.00 11.6 13 15 HF For finishing turning PK 0.3-1.0 •Sutable for haevy duty cutting dueto strong cutting edge.3.0-15.0•Wide cutting . chip control force range with lowP 0.05-0.3MIIIIIII0.1-2.0 •Excellent chip control in steel,stainless steel, grey and nodularcast-iron.•Suitable for both diameter turning. boring and outer For semi-finishing machining PM 0.15-0.5II0.2-6.0 •First recommendation for medium cutting of carbon steel and alloy steel•Alternative chipbreaker for. finishing iron and light cutting of castP•Suitable for feneral field. PositiveMedge shape of blade, performance ofsharp cutting. For semi-finishing turning0.2-0.5•Excellent chip control at wide1.0-4.0range of cutting conditions•Suitable for stainless steel cutting. For stainless finishing turning • - semi finishing to finishing under For roughing turning with high efficiency high feed rate is 0.05-0.3MsIIIIIII0.1-1.0 adopted under the condition of smallcutting depth. P•Due to the latest chipbreakerMdesign, it can obtain good chipcontrol and good machining surfaceK0.3-0.7 •suitable for internal and external3.0-7.0roughing of steel , stainless steeland cast iron material. accuracy. •The extremely sharp edge and high rake angel design especially is suitable for stainless steel & softysteel. AL For Aluminum cutting BM 0.1-0.3MII For semi-finishing machining•Has a wide range of applicationsfor stainless steel.• Can effictively solve machiningN ISL 0.03-0.4IIIIIII I I0.1-4.0difficulties such as chip breaking Wide available chip control range• - from medium-finishing to mediumroughing.•High speed of finishing operation. 0.5-1.5 and sticking phenomenon in the stainless steel processing, which can obtain higher machiningefficency. For finishing turning MsN For Light-alloy, Stainless-steel machining 0.03-0.3sIIII I I• Sharp cutting . cutting force edge generates low0.06-1.7• Specially designed tough maincutting edge.•Suitable for finishing machining ofheat resistance alloy, titanium alloyand other aerospace parts.•Loght cutting chip breaker with low. cutting force, high reliability anduniversalityProblem free cutting. • Sutable for cutting of low carbon steel, stainless steel, aluminum. HS For Medium cutting of stainless steel 0.1-0.4M •Exclusive design for stainlesssteel cutting provide longer tool life. 1.0-4.0 •Wear resistance have beenreinforced through high rake angle of chip breaker land. No slot ForRoughing turning K > 0.05-0.6IIIII I1 •For grey and nodular - cast iron. 0.3-12.0 •Broad application roughing. range for 077 078

Общий каталог TooTool

Общий каталог TooTool Каталог TooTool монолитные фрезы

Каталог TooTool монолитные фрезы Каталог TooTool техническая информация 2

Каталог TooTool техническая информация 2