Каталог TooTool техническая информация 1 - страница 37

Навигация

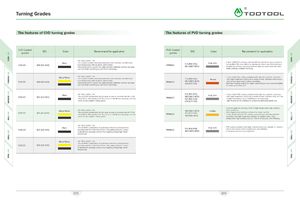

Turning Grades A\ The features of CVD turning grades The features of PVD turning grades CVD Coatedgrades ISO Color Recommend for application PVD Coatedgrades ISO Color Recommend for application • MT - TiCN + AI203 +TiN Black • CVD coated carbide combining extremely hard substrate can withstandTCK5205K10 (K05-K20)high temperature without plastic deformation .•Recommended for ductile iron, high strength malleable cast iron and grayTPM8115P15 (P05-P25)Gray dark • 2-4pm TiAIN PVD coating combined with the submicron crystal matrix, ithas excellent film-base adhesion, abrasion resistance and heat resistance.M15 (M05-M25)•Suitable for stainless steel, heat-resistant alloy and other materials under cast iron finish machining to semi finish machining. stable working conditions finishing. Black/Yellow • MT -TiCN + AI203 +TiNCVD coated carbide combining extremely hard substrate can withstand 3-5pm AITiN PVD coating combined with ultra fine particles' substratesP15 (P05-P25)Brozenwith high-toughness suitable for a variety of steel, stainless steel & supor high temperature without plastic deformation .TCK5305K10 (K05-K20)•Recommended forductile iron, high strength malleable cast iron and grayTPM8315M15 (M05-M25) alloy at high speed and continue machining.S10 (S05-S25)Optimized coating stability for higher wear resistance and thermal stability cast iron finish machining to semi finish machining. in a wide application field. Black • MT-TiCN+AI203+TiNTCK5215K15 (K10-K25)•The excellent combination of high wear resistance substrate and MT-TiCN,thick AI203, TiN coating is the first choice of ductile iron and gray cast iron,TPM8125P25 (P15-P35)M25 (M15-M35)Gray dark • 2-4pm TiALN PVD coating combined with ultra fine particles' substrateswith high-toughness suitable for a variety of steel, stainless steel, cast ironK25 (K15-K35)& high temperature alloy in finishing to semi-finishing. which allows a higher cutting speed. S20 (S15-S30) • High thermal shock resistance is suitable for light interrupted cuts. • Universal grade for stainless, HRSA & high-temperature high hardness TCK5315 K15 (K10-K25) Black/Yellow • MT -TiCN +AI203 +TiN•The excellent combination of high wear resistance substrate and MT-TiCN,thick AI203, TiN coating is the first choice of ductile iron and gray cast iron,which allows a higher cutting speed.TPM8225M20 (M15-M25)S15 (S10-S20)H10 (H05-H15)Golden alloy machining.•High chipping and welding resistance for longer tool life.•2-4pm AlCrN+AICrSiN PVD coating combined with ultra fine particles'substrates with high-toughness suitable for stainless steel , high- temperature high hardness alloy & HRSA in finishing to semi-finishing. • MT-TiCN+AI203+TiNBlack•The excellent combination of good wearresistance and toughnessTCK5225K25 (K20-K35)substrate and MT-TiCN, thick AI203, TiN coating is the fisrt choiceof ductile iron and gray cast iron for roughing cutting high metalTPM8135P35 (P20-P40)Gray dark • PVD coating combined with high-resistant substrates, suitable for stainlesssteel & low carbon steel in roughing to semi-finishing.M35 (M30-M40)•Good wear resistance and toughness remove rate. Black/Yellow • MT -TiCN +AI203 +TiN The excellent combination of good wear resistance and toughness TCK5325 K25 (K20-K35) substrate and MT-TiCN, thick AI203, TiN coating is the fisrt choice of ductile iron and gray cast iron for roughing cutting high metal remove rate. 073 074

Общий каталог TooTool

Общий каталог TooTool Каталог TooTool монолитные фрезы

Каталог TooTool монолитные фрезы Каталог TooTool техническая информация 2

Каталог TooTool техническая информация 2