Каталог TooTool техническая информация 1 - страница 36

Навигация

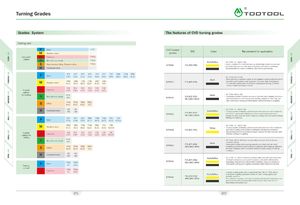

Turning Grades A\ Grades System The features of CVD turning grades Cutting tool P Steel TP20MStainless steel CVD Coatedgrades ISO Color Recommend for application Uncoated Cast iron TPK01 carbide N Non-ferrous metal TPK01sHeat resistant alloy, Titanium alloyTPK01HHardened steel Black/Yellow • MT-TiCN +TiC + AI203+HNTCP9305P05 (P01-P10)• Stable conditions for steel finishing can obtain high metal removal rate.• Excellent resistance to crater wear and plastic deformation resistance.Recommended for stable conditions. Wet and dry processing P Steel TCP TCP TCP TCP TCP TCP TCP TPM TPM TPM9305921591209225932593359345811581258135 MT-TiCN + AI203 +TiN TPM TPM TPM TPM TPM TPMStainless steel81158315812582258135930 TCP9215 P15 (P05-P20) Black • Wear-resistance materials coated on the gradient sintered substrate whichhas both good hardness and toughness. Can bear high temperatures.•For steel and casting steel finishing to roughing processing. Continue cutting to light interrupted cutting. TCK TCK TCK TCK TCK TCK Coated Cast iron 5205 5305 5215 5315 5225 5325 carbide for turning Non-ferrous metal TPDL025 Black • MT-TiCN + AI203+TiNTCP9225P25 (P15-P35)M15 (M10-M20)•Combining excellent fracutre resistance substrate with chipping resistanceand heat resistance AI203 increased stability, suitable for steel and cast steel continuous cutting and interrupted cutting finishing to roughing. s HRSA TPM TPM TPM TPDL831581258225025 H Hardened steel HX HX200400 MT-TiCN +TiC + AI203+TiNBlack/Yellow•Universal grade combining substrate with wear resistance and toughnessTCP9325P25 (P15-P35)M15 (M10-M20)and AI203 coating with oxidation resistance and fracutre resistance ,suitable for steel and cast steel continuous cutting and interrupted cutting P Steel TCP TCP TCP TPM TPM TPM TPG TPK93309340935081158125813542354235H finishing to roughing. Stainless steel TPM TPM TPM TPM TPM TPG TPK8115831581258225813542354235H • MT-TiCN +TiC + AI203+TiNYellow•Universal grade combining substrate with wear resistance and toughness TCP9120 P20 (P15-P25) and AI203 coating with oxidation resistance and fracture resistance. Coatedcarbide for TCK TCK TCK TCK TCK TCK TPKCast iron5205530552155315522553254235H • Special treatment on the outermost layer. Suitable for steel and cast steelmedium cutting to roughing. milling TPDLNon-ferrous metal025sHRSATPMTPMTPMTPDL831581258225025 • MT-TiCN+AI203+TiN High-strength alloy substrate with thick wear-TCP9235P35 (P25-P40)M35 (M25-M40)Blackresistant coating.interrupted cutting and roughing operations in steel and cast steel.Combining excellent fracture resistance substrate with chipping resistanceand heat resistance AI203 increased stability in wide ranges of cutting conditions. H Hardened steel HX HX200400 Turning Steel TTIN TTIN303025 TCP9335 P35 (P25-P40) Black/Yellow • MT-TiCN+TiC+AI203+TiN High-strength alloy substrate with thick wear-resistant coating has good good toughness and plastic deformation.M35 (M25-M40)•Machining steel and cast steel in bad conditions, Edge line security forinterrupted cutting and roughing operations high metal removal rate. cermet Cast iron TTIN TTIN 30 3025 A tough carbide grade with a moderately thick TiN-MT-TiCN-AI203 Black/Yellow coating for roughing operation of steel at lower cutting speed and TCP9345 P45 (P30-P50)M45 (M30-M50) unstable condition•The substrate-coating combination provides unbelievable toughness and operational security allowing high metal removal rates even in most demanding interrupted cuts. 071 072

Общий каталог TooTool

Общий каталог TooTool Каталог TooTool монолитные фрезы

Каталог TooTool монолитные фрезы Каталог TooTool техническая информация 2

Каталог TooTool техническая информация 2