Каталог TooTool техническая информация 1 - страница 169

Навигация

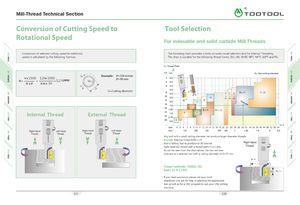

Mill-Thread Technical Section A\ (B>VX Conversion of Cutting Speed to Tool Selection Rotational Speed For indexable and solid carbide Mill Threads Conversion of selected cutting speed to rotational The following chart provides a fairly accurate visual selection tool for Internal Threading. speed is calculated by the following formula: The chart is suitable for the following thread forms: ISO, UN, WHIT, NPT, NPTF, BSPT and PG. P= Thread Pitch A TPI mm D= Tool cutting diameter Example: V=120 m/min VxlOOO 120x 1000N==1274FIPMJtxD3.14 x 30 D-30 mm 4 6.055.0 6 4.0 D=Cutting diameter 3.5 —83.0 — r '% oo D= 21 D= 29 10 2.5 10 iio Q Q 12 2.0 0 87161.5201.25241.0 —320.75y-4 I ft D=9D = 12 r 48 0.5 3 d mm 4 5 6 7 8 9 10 11 12 1314 15 16 18 20 22 24 26 28 30 32 34 36 38 40 44 48 52 58 64 inch 1/4 3/8 1/2 5/8 3/4 1 1.25 1.5 2 2.5 Any tool with a small cutting diameter can produce larger diameter threads. Example: Internal thread M30 x 1.5: Find a Milling Tool to produce d=30 Internal Right Hand right hand ISO thread with a thread pitch P=1.5 mm. Thread As can be seen from the chart above, the two red linesintersect at a selected tool with a cutting diameter of D=21 mm i d= 30 Chosen toolholder: SR0021 H21 Insert: 21 N 1.5 ISO If you need assistance, please call your local distributor and ask for help in selecting the appropriate tool as well as for a CNC program to suit your CNC milling machine. 337 338

Общий каталог TooTool

Общий каталог TooTool Каталог TooTool монолитные фрезы

Каталог TooTool монолитные фрезы Каталог TooTool техническая информация 2

Каталог TooTool техническая информация 2